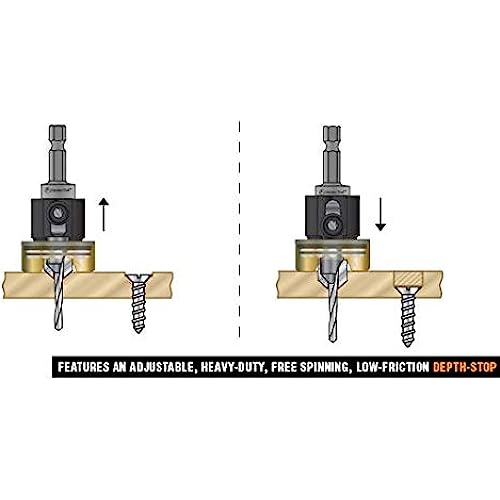

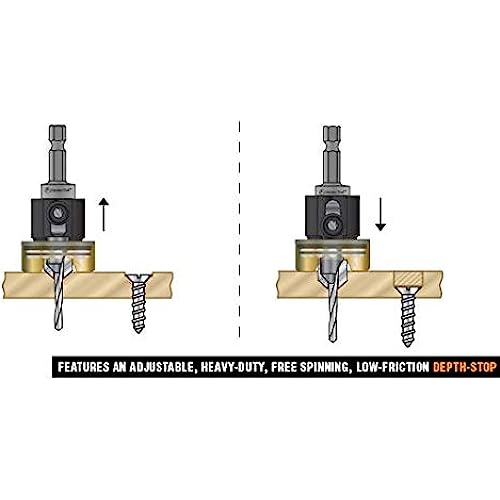

Amana Tool - 55229 Carbide Tipped 82° Countersink with Adjustable Depth Stop & No-

-

Dawn Zieme

> 3 dayEasy to use, easy to adjust, and works great.

-

b.b.

> 3 dayIf I could give this zero stars I would...bit broke off on the 4th hole I drilled. See photo and note the chipped carbide on countersink. Waste of $$$. EDIT: Thought about it, and decided the cheese-grade included drill bit was the real issue. Ordered another one, measured the bore with a minus pin gauge set, and determined it to be approximately .128. Figured the through hole bore on these countersinks will accept a #30 drill bit. A #30 is .1285, which is .0035 over a 1/8 drill bit. This tool is designed for #8 screws, which have a minor diameter of .123. So I got the stub-length (which is the same length as the supplied cheese-grade bit) #30 drill bits I also reviewed, inserted (snug fit, good for concentricity, which is what you want when counter-sinking!) into the Amana body and appear to be good to go. Spend a little extra $$$ on better drills and you may have a better result. I think the carbide chipped when the original drill bit broke off in my project. That still bothers me, but these are better designed than the vast majority of sleeve-type countersinks that inevitably wobble all over the place when you adjust depth. Three stars for design only, one star originally for cheap included drill bit. On the plus side, with clearance of less than .001 or so, the bits nice and tight in that bore and there is no perceptible wobble - even when adjusting the depth of your hole. Locks up tight as a bank vault.

-

Pookie

> 3 dayThe ability to drill stopped counter sink holes is a game changer for me. Ive been working on making fine furniture, and one of the things that has been an issue for me is consistency with countersunk screw holes.

-

MrJD-woodworks

> 3 dayGreat product!! Very practical and comfortable in use. Just a bit expensive

-

A. Cardillo

Greater than one weekI’ve seen YouTube woodworkers using these, and decided to try one. It’s so much better than those other combo bits. The stop that’s attached makes it much easier, and it spins on its own so I doesn’t destroy your wood. I would like the actual drill bit to be longer, but I will probably just replace that.

-

I-Buy-A-Lot-Of-Stuff

> 3 dayI had to counter sink some skateboard holes. This counter sink did the job. It’s build very well and it is very easy to use. I had a few small adjustments to get the right depth and it was easy. It left very nice clean holes in the wood. This counter sink it worth the money and its worth having in your tool collection.

-

Nancy L. Dyar

> 3 dayMy grandson said it was just what he needed and seemed to be please with it overall.

-

Tom Marshall

Greater than one weekLove this product. Wish I bought it a long time ago. Makes drilling countersink holes fast and easy. No more over-drilling holes or starting and stopping to get just the right depth. With this little device, it is always right the first time.

-

Chinacat1951

> 3 dayA bit pricey, but it does work, It functions as a depth stop. A valuable addition to your tool box for hard woods. you will have to adjust the way you use it on softwoods, simply because it is a softwood.

-

Marc Ryals

> 3 dayI dont know why I never bought this sooner. Its amazing! I used to either drill a hole then use a chamfer bit or I tried those drill bits that have an adjustable one on them. Never really cared for either way but THIS thing is Heaven. I find myself reaching for it every time I need to put in a screw. Im going to buy a second one just in case someone accidentally walks off with this one. Lol. Amana has a huge hit with this. Thank you Amana.