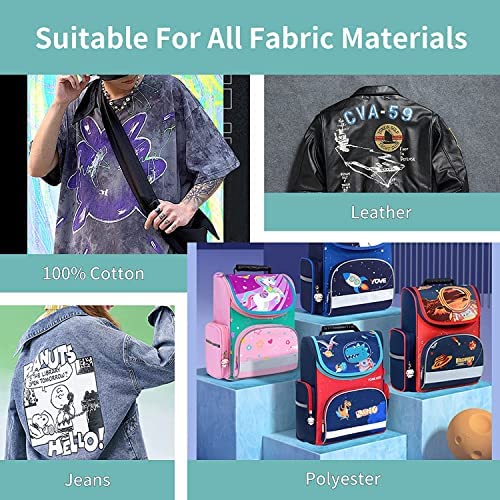

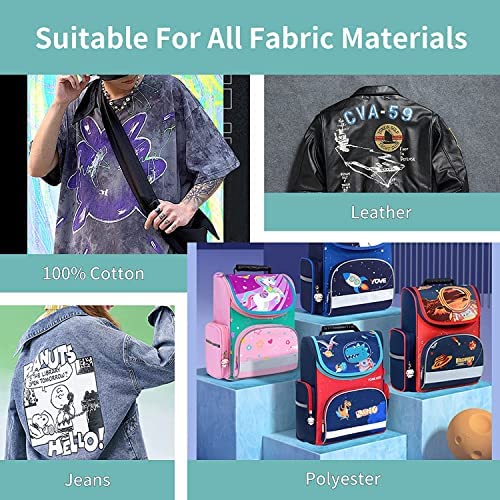

Jecqbor DTF Powder White Digital Transfer Hot Melt Adhesive, 400g/14oz DTF Pretreat Powder for DTF Printer Direct Print on All Fabric Include Jeans Cotton T Shirt Textile etc

-

Tomboy at heart

Greater than one weekA great assortment of needed refill inks for my DTF printer. These bottles are big at 100ml each you are getting your moneys worth, if evaluating buying new cartridges versus refilling. Love they have anti-clogging characteristics. Very bright and vivid colors. These heat transfer inks print smooth for you to later add your transfer powder, very pleased.

-

Cupcake

> 3 dayDTF Transfer Film Paper PET Heat Transfer Paper A4 (30sheet), Double-Sided Glossy Clear Pretreat DTF Film for DTF Epson Inkjet Printer, Direct Print On T-Shirts Textile (8.3 x 11.7) I don’t have a proper DTF printer or inks, but I do have an inkjet printer and an Epson Ecotank loaded with sublimation inks, and I saw a number of youtube videos about doing bootleg DTF, so I decided to give it a go! Bottom lining it: with some trial and error, you can get pretty great DIY results using this product with sublimation or inkjet inks. In my experience, the sublimation ink produced a better print, but the inkjet did work. I also just want to caveat this with the expectation that these are very nice DIY results, but I wouldn’t put myself out there as a professional, because I don’t know how well the bootleg results would last over time. I’m using this for my own shop promo products that I wanted to print on cotton, not items I’m selling. And I’m not printing on anything that will be laundered or take the abuse that garments or a heavy-duty item would. I would not feel comfortable selling transfers without some serious trial and error. That said, I’m really happy with my DIY results, which look much better than your typical inkjet iron-on transfer material and have a lot more detail than my cricut/htv options (and a lot less time/work). And unlike straight sublimation, this works on cotton. But I am not a professional printer and can’t rationalize buying a proper DTF printer just for my occasional promo items, so these are purely DIY level results. I’d still go with a pro if I needed a large run or garments, but for small runs of promo items and one-off custom items for personal use, yay! So, if youve done this before and you just want to know if this product does what its supposed to do, Id say yes. If you want more details on trying it for DIY projects, read on... I used this film with a random brand of powder. Based on this, and the fact that this paper/film explicitly said it *wasn’t* for inkjet or sublimation inks, but ended up working, you might be able to get most random combos to work successfully with some trial and error. First of all, my powder didn’t include any instructions, so I got my info from you tubers and Professor Google. This paper includes instructions, but they were for a professional setup, and didnt so much apply to me. Which is to say, I did what the said not to do. :) Challenges with printing with a regular printer: Mirror/Reverse/Flip horizontally: If your printer doesn’t have this setting, you’ll need to mirror the original art. Feeding: DTF paper is slick and a regular printer isn’t designed to handle this substrate, so you’ll probably have problems (one printer jammed, another picked up the paper but would only print a couple of lines before stopping). I put a strip of washi tape across the top on the slick (non-printing) side and that was enough for two of my printers to grab it; the third would only grab it when I taped a sheet of copy paper to the slick side Streaks: Use standard print (not high quality) to minimize streaks. Experiment until you get as clean a print as possible. My ET-4750 (regular inkjet ink), which uses dye-based inks (not pigment-based) had the most trouble (both with feeding and a clean print). My WF-7720 made the cleaner print of the inkjets. Color: Both inkjets produced brighter colors than the sublimation inks, but the sublimation ink did really well with the white portion of the design, which was just clear/fabric color with the inkjet Coating the wet print with powder was straightforward—just sprinkle the powder over the wet print, then move the page side to side so the powder flows across it evenly, then tap off the excess. The printing will look like it’s coated with a fine layer of fine sugar. You can keep reusing the excess powder. I use a small jar to pour the powder and a letter-sized plastic bin, and afterwards pour the excess back into the jar. Challenges with curing (the trickiest step): Heat press: While pros seem to cure with a hovering (not closed) heat press or specialized oven, my budget press wouldn’t cure the powder. Maybe I wasn’t hovering close enough to do the job, but the teflon fabric on the top of my press is saggy. (If your heat press is better than mine, the suggestion seems to be about 2 minutes at 325F.) Then I tried an old toaster oven with varying results. Try about a minute or so at 150. All this is going to vary with the peculiarities of your own oven, so youll need to experiment. Keep in mind this does produce fumes—nothing scary if you’re only doing a sheet or two, but you’ll definitely need ventilation if you cure more than that. Further, I wouldn’t do this with a toaster over you’re cooking in. When its done curing, it will look glossy, and be continuous with an orange peel appearance rather than a dry grainy appearance. Pressing: This was fairly straightforward. Working on 100% cotton muslin and canvas, I used my heat press at 325F, did a 15-second pre-press, a 15 second press covered with parchment, then a cold peel to remove the film, and another 15-second press with parchment. Voila! Dont skip that final press--its critical for getting the transfer to soak in so you dont have any visible edges. Results: While I liked the more vibrant look of the inkjet results, you can’t beat the white results with the sublimation ink (to be clear, it doesn’t print white, but the actual pale gray of the white does print in all formats—it’s just that perhaps something about the sublimation ink binds better with the powder to produce a better “white” effect in the final result? Conclusion: If you have an inkjet or sublimation printer, give it a whirl! Do know that you might waste a lot of paper before you get good results, but it’s a lot better looking and versatile than old-skool inkjet transfer paper.

-

MaxDog

> 3 dayThese are good DTF film paper to be used in combination with sublimation ink and DTF white or black power. I read some of the other reviews for this product and some buyers complained about this film paper not transferring the sublimation ink onto their cups and other (standard) sublimation blanks. This is NOT the right product for those applications. In those cases, the buyers should be purchasing sublimation paper -- not DTG transfer film. Another person complain that their regular inkjet ink didnt transfer with this film, which it isnt design to do. If you read the product description, you will need either DTF or sublimation ink -- you cannot use standard inkjet ink for DTF or sublimation purposes! Note: If using sublimation ink, you need to get the DTG white or black power with this product. After watching some youtube videos, I wanted to do this sublimation hack for pressing onto cotton fabrics. This product AND the DTF power works fine. I need to play around with my heat press settings and find the optimal setting for pressing the transfer film. Im not sure which item is to blame, but my transfer images are peeling from my cotton t-shirts. I will update this review when I can pin point the issue. You also need to calibrate your printer and make sure you are not using a lot of ink on it... if you do, the rollers on your printer will leave streaks. Do not use the cardstock or heavy weight setting for the printer, since that seems to use a lot of ink. You get 30 sheets of transfer paper with this purchase. I was disappoint that my packing did not look anything like the product page. I got my transfer paper in a plastic bag enclosed in a plain, thin brown box. The instructions were lacking and I couldnt tell which side to print on. The price of the transfer paper is comparable to other products in the market. Thank you for reading this review, I hope you found it helpful.

-

Alicia Villalpando

Greater than one weekFirst time using this brand. It did a good job of sticking and melting. Print adhered to cotton shirt all looks well. Longevity of the product is unknown. I hope to see it last at least 25-50 washes. Glad this item came in a cap sealed container.

-

Melissa

> 3 dayVery easy to use. Works well with the right dtf paper.

-

Kristopher G.

> 3 dayPros: This heat transfer paper is pretty inexpensive and works very well. The pictures printed on them are very clear and crisp. They transfer easily with heat and once transferred the pictures look very good. They work much better than expected for the price. Overall: This heat transfer paper works great for a great price. I highly recommend them.

-

Jeannie

> 3 dayI am so glad I decided to try this to use with sublimation. I love the results when it is do correctly. And to learn that it didnt always have to be sublimation ink. You can use with the inkjet printers. Wow I cant stop using it

-

Fredco

> 3 dayWhile I am new to the sublimation world using an inkjet printer, these sheets perform really well and seem to work at a variety of temperatures as well as settings on the printer you use. It does take some time as or rather if you go from brand to brand of papers and so once you get this dialed in I would stick with this product. The finish on the paper does come out glossy on the transfer once everything is set up and the results actually have some pizazzs

-

Sally sowers

> 3 dayThis product does exactly what it says …. Will order again…

-

Kindle Customer

03-06-2025Had zero issues using this powder! Highly recommend for the dtf sub hack.