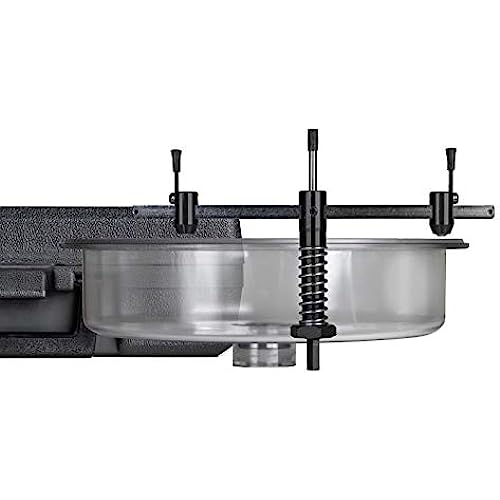

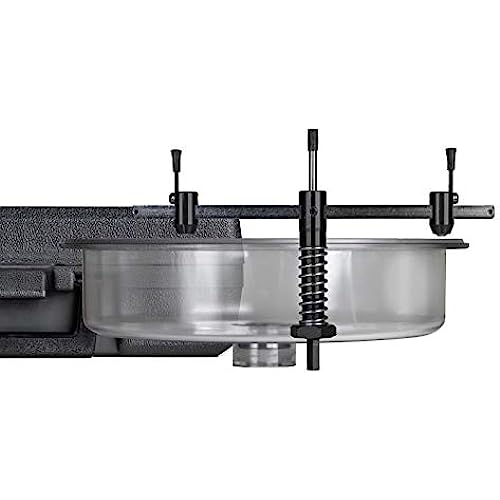

Jonard Tools AHC-10, Professional Grade Round Hole Saw Cutter, Includes Dust Shield and Case, Cuts Plywood Plasterboard Sheetrock Acrylic Up to 1 1/16” Thick, Adjustable Hole Size 2.2” to 10”, Silver

-

KD9BWI

> 3 dayWorked great for cutting in supply diffusers on drywall. I decided on a new construction job to try its claimed ability to cut plywood/osb. The trick with drywall was to go slow with a fast drill speed to keep the teeth from jamming. I did the same thing on OSB, it tried to cut but ended up snagging and breaking the pilot bit before the drills anti-kickback could do its thing. The saw is also VERY particular about keeping COMPLETELY or else its try to skip.

-

HiVac

> 3 dayI don’t understand all the “it doesn’t work with a cordless drill” comments. It works just fine! I cut four holes in my ceiling in about 5 minutes for surround speakers (I chose this model because the Sonos architectural speakers require an 8-1/4” cutout). And it worked perfectly with my dewalt 20v cordless drill. You need to spin it fast and cut slowly (maybe 10 seconds in drywall)...but there is no mess, and the hole is perfect! Highly recommend this tool!

-

Q

> 3 dayGot it for Christmas Gift last year and my brother still uses it.

-

JD Snacker

Greater than one weekI purchased this to cut various sized holes in my ceilings for recessed lights and whole-house audio speakers; 50+ holes of various sizes. This is a substantial, heavy duty, super sturdy/rugged tool…. It is not flimsy or “cheap” in construction. Works like a champ and the dust shield really helps contain the drywall dust. The only recommendation I would make for anybody considering this tool is to buy the version with the vacuum port to further mitigate the dust by eliminating the need of dumping it. I did not know a version with a dust port was available when I purchased this.

-

Francesco

Greater than one weekThis is a well-made accessory. Yes, you’ll need a drill with adequate torque, but what handyperson or tradie who’d spend $80+ on this hole saw doesn’t own a modern cordless drill with gobs of torque? My non-Fuel 18V Milwaukee had zero trouble with it. A side handle would definitely help stabilizing it, but I still had no issues. My only beef is that what seemed like the logical way to set the size — on the flat (outside) of the blade — is in fact wrong; you have to slide the blade holder *past* the measurement and line up the curve of the holder with the marking on the beam. Easy enough to see the wrong size on a smaller hole, but setting for an 8¼” diameter for my first try it wasn’t noticeable until I finished the cut. Now waiting for the mud to dry after putting the plug back in the wall (because it’s the only way I’ll be able to re-cut it)! I saw the error and adjusted the tool and cut three other holes in around five minutes. I have another couple of dozen holes to cut here and at another property. Oh. And really pay attention to the location of studs, blocks or furring strips/joists in the cavities you’re trying to hole. The blade will bind and the drill will buck in the blink of an eye! That first hole taught me *two* lessons, there was a block where none were expected. Overall an incredibly useful addition to my tool box.