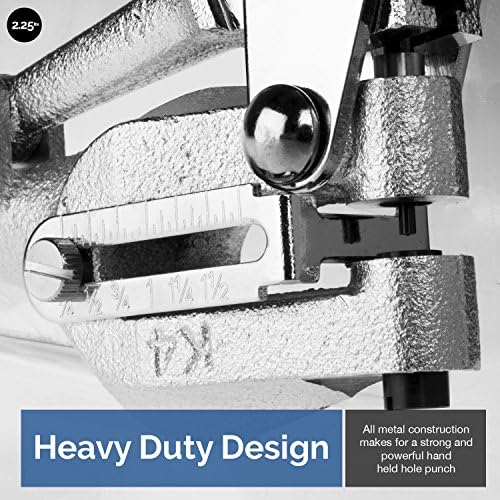

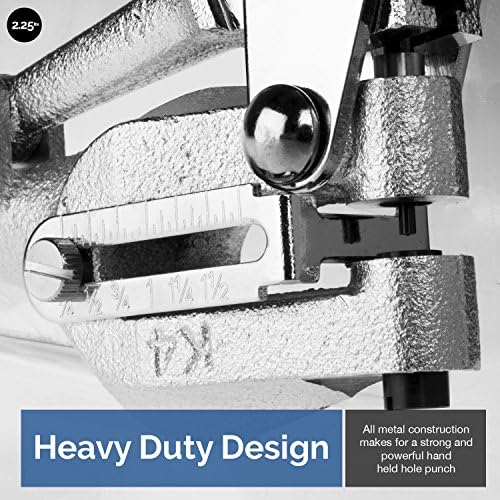

NEIKO 02612A Hand Held Power Punch and Sheet Metal Hole Punch Kit, Various Size Hole Punch in 3/32 to 9/32, Heavy Duty Hole Punch for Metal, Leather, Compound Leverage Punch

-

PLM

> 24 hourIve been using this tool for about four months. It is a solid piece of work. You are not going to knock any holes in anything more than 20 gauge sheet metal with any kind of comfort, quickness or ease. I use this tool to punch holes in 28 gauge sheet metal dog tags for the local sports team I support. It works well for that. PROs- Love the available size hole punch sets, love the quick change between sizes. I use two sizes every time and the change is quick and easy. The female die, male die, and handle attachments are hand (finger) adjustable. Really like this tool for what I bought it for- punching holes in thin gauge sheet metal. Does a great job in a variety of sizes. price is great. Tools works well. Die change is very easy. The case is functional and supports changing dies and sizes. Highly recommend. Index points on dies help ensure holes go where you want them. You can adjust the female die to create knock-outs, hanging chads, and clean holes. The mechanical advantage of the tool makes punching holes in thin gauge metal easy. Punching holes with one hand is easy. thats good because keeping things on target and aligned is tricky; not difficult, just tricky and requires practice. It still takes two hands to open the tool and clear punched metal. The main point here is the tools design facilitates freeing your project as well as it does punching the hole. CONs- very worthless, not sure why its included, afterthought of a screw driver. Really?????? I mean, why bother if the worthless piece of tinfoil is all you can do? You dont need this thing. It really doesnt detract from the function of the tool. However, it is listed as a selling component and isnt worth shipping costs to include. I think they had to go out of their way to find a metal as soft and pliable as the type they are using. Dont breath too hard or youll bend it. I think holding it in your hand too long softens it up. Very minor point but, disappointing none the less.

-

Srinivasa

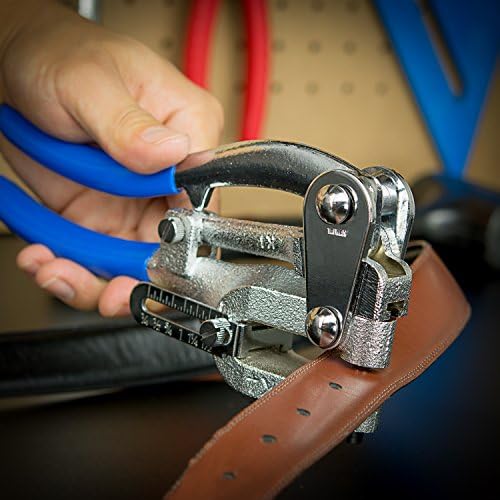

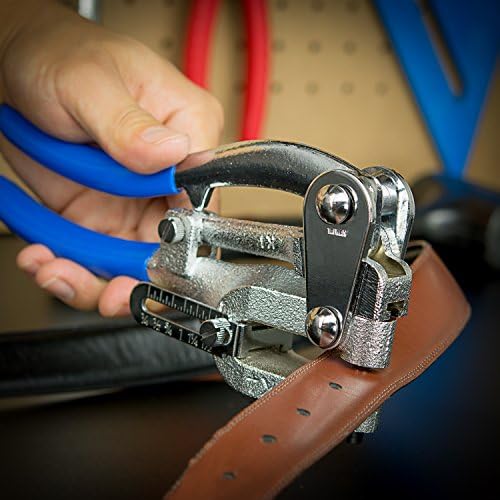

> 24 hourThis punch is built like a tank. It weighs more than 2 pounds -- but it is designed so well that you can hold it comfortably and use it easily. It comes with the smallest punch already installed -- so, dont freak out when you open the box and see empty slot where the 3/32 punch and die are expected to be. You will need to see online videos to figure out how to change the punch bits. When you press down on your belt or handicraft, it is almost as though some hydraulic powered press kicks in -- and the bit will punch through the toughest belt *cleanly* and with a snap. It was a breeze using it, and I am very happy I bought it.

-

Jennifer Bridges

> 24 hourBought three of these as gifts. All recipients like them and say they work well on leather.

-

Yoko

> 24 hourI am thin and have difficulty in finding a belt that fits me especially when I want to buy one on sale. I bought some belts on-line but most of them were too big. But thanks to this new tool, which is quite easy to use if you study how to use it by some videos on Youtube, I can finally wear them. It is not easy to adjust the distance of the hole you want to make to the edge but I tried first on taper. To be 100% sure, you should first make a right mark on the belt by pressing the tool just a little bit. If the marked point is in the middle, it is good to go. For the upper belt, I made 3 holes on the right and for the lower belt, I made 2 holes on the right. They look quite OK, I think! I am proud of myself as well!

-

Myself

> 24 hourIts not hyperbole to say this revolutionized the way I make small aluminum brackets and fixtures. If youre on this page, you will find it useful, stop debating and just buy the thing. I was introduced to this tool on a jobsite a few years ago, and immediately bought my own. One of the best bang-for-the-buck tool purchases Ive ever made! Punching doesnt leave the area covered in dust like a drill, and that means I can often take the punch to the work wherever it is, rather than bringing the work back into the shop to contain the mess. Its also purely muscle-powered, which can be a pain if the angles are awkward, but it means no batteries to charge, and nearly silent operation. Consider how those two attributes would change your workflow! I wish it had longer levers, but thats not really a Neiko complaint; this is a straight-up clone of the genuine Roper Whitney punch thats been sold for decades. When I break a punch, I order American-made spares from Roper Whitney, but thus far Ive only broken one. The Neiko knock-off tool itself seems fine, though the thumbscrew is bound to fail someday -- they couldve improved on the original by putting a beefier shoulder screw in the obvious place, but didnt. The product photos show a blue case, mine was black, and they dont show how the punch fits into the case, which is just fine. I use mine primarily on aluminum. I can get through 1/8-inch stock if I put the punch on the chair and give it some grunt. 1/16-inch goes through like a paper punch. I occasionally use it on nylon and ABS plastic, which of course it barely notices, and I showed my leatherworking friends who were *completely blown away* by this revolutionary bit of centuries-newer-than-their-other-tools wizardry. One caveat: Due to how far the chin and nose stick out past the active area, this cant punch a hole right back against the wall of an L-channel, and due to the size of the chin, it cant get into small U-channel. I still use the drill press for those when theyre needed, but Im pretty adept at avoiding those situations entirely so I can completely eschew drilling.

-

Moon-tai Yeung

> 24 hourThis is what one would call a heavy duty tool. The whole thing is solid casted metal machined to good precision. Heart of the tool are the punch and die pairs. There are 7 of them, from a little less than 1/8 to a little over 1/4. All pairs fit well together out of the box. The larger sizes tend to fit looser though. I tried all of them on an old computer case and all holes came out clean. Hole sizes were also accurate. In terms of usability, I recently used it in a project to punch around forty 1/4 holes on 26g flashings. This is what I found: 1) The throat depth (1-3/4) is good enough for most uses. But the jaw opening is pretty small, 1/4 according to spec. Since the jaw is fixed, you have to retract the punch side all the way and unscrew the die side way down to get that. My flashings has a 1/8 lip and getting it in and out of the jaw was awkward. 2) Since the jaw is fixed and narrow, it is very difficult to center your hole by sight. One option is to use a center punch to mark the hole first and then use the pointed tip of the tools punch to center on the mark by feel. What I ended up doing was to turn the tool upside down to see my pencil mark through the die. Then I applied small pressure until I see the dimple caused by the punchs pointed tip at my mark before punching through. 3) To make good holes, the die must protrude a little above the bottom of the jaw. However, the die only fits (screw-in) loosely, so you must check/adjust it for every hole. 4) On the other hand, you should not protrude the die into the jaw to much; otherwise, the handles will spread very far apart and you will need two hands to operate the tool. I made a mistake at the beginning and made some holes one size (1/32) too small. I switched to the right size and was able to make clean holes over the smaller ones. Overall, I was impressed. By the way, the tool is made in Taiwan, which I found to have better QA than China. Even so, I think the 16g capacity is overstated.

-

Bubs McGillicutty

> 24 hourThe holes that this cuts are great. The tooling is tight, and thats important. I suggest these as design possibilities: -Use a pin in stead of a screw to hold the handle together, for easier changing of dies (I will probably glue a wing nut on mine). -Change the design of the handle slightly so the user can drop the dies in at the top more easily. Its a little bit of a dance to get them out, but you get the hang of it.

-

MarDav

> 24 hourIt punches perfect holes in the aluminum material that Im using. The only improvement that I can see is to make the handles ratcheting. Other than that it is a good tool to have around.

-

Julie

> 24 hourI tried to use regular christmas light clips (for the roof flashing) but the garden lights were way too heavy. I knew I needed to punch some kind of hole into the flashing in order to zip tie them. This works great. I used the largest hole setting which is more than big enough for zip ties. Its easy to assemble and disassemble when swapping out bits. This works easily on sheet metal for flashing, I imagine anything thinner/softer would be easy. The back end was small enough to go under the flashing, but only where it was loosest. If you have to punch something thats flush against another object, you wont be able to. Mind you, I did this while on a tall ladder near the rooftop. I was happy with the results. However, its best to punch holes into whatever youre trying to punch holes into BEFORE hanging it or fastening it to whatever youre ultimate goal is.

-

NISSI SIGNS

> 24 hourPara perforar lamina de aluminio 0.40