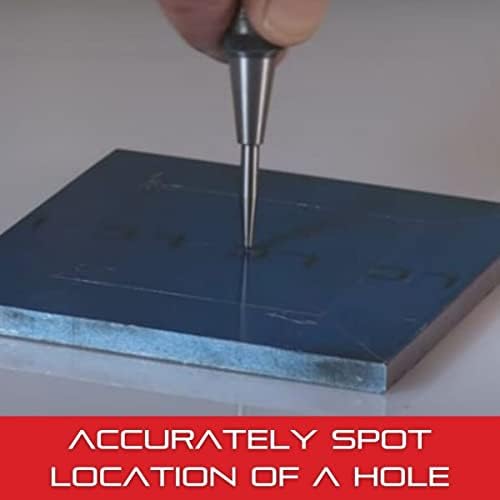

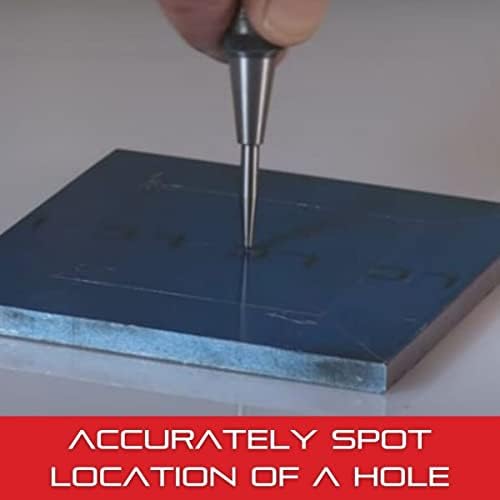

Starrett Automatic Center Punch with Hardened Steel Metal - 100mm Length, 11mm Punch Diameter Tapered Point - 18AA

-

Jeffrey A.

> 24 hourWonderful little center punch. It only rarely misfires and you have to do it again, but normally it is excellent. It is light duty and only good for soft or thin metals.

-

Ms. Jazlyn Bahringer

> 24 hourBeautifully made solid steel center punch. The adjustable action is helpful. Feels like a lifetime tool in your hand. This one is small which I like for getting in tight spaces to mark pieces while they are held against each other.

-

Matthew J. Bibbee

> 24 hourIt seems to catch and not punch sometimes but removing it and resetting the punch mechanism it hasnt completely failed yet.

-

David Hoffman

> 24 hourThis punch is small, which is a plus, and very dependable. I use it anytime I want a small centering hole. Just push and punch. Well worth getting. The self tapping feature is easy and reliable. Dont know why it took me so long to find this device. No more hammering. Now a simple one-handed operation. Listen for the click and you know you have a made small centering mark.

-

Anita and Gerry

> 24 hourWas too weak to produce a dimple in the metal sheet I wanted to drill.

-

Cade

> 24 hourThis punch is super high quality, I’ve had it a few months and still working great. But I would say it’s not the best for hard metals, which is what I bought it for. If you are using for marking wood & soft metals (aluminum, brass) should be fine but not so much on steel. I would recommend getting the heavy duty version for about $10 more.

-

Greg

> 24 hourProduct quickly arrived as promised. This small punch makes a tiiiiiny indention, enough for a drillbit to lead. I do wish was more potent and made a larger indention in sheet metal.

-

Bri

> 24 hourAfter yet another Harbor Freight punch wore out, I decided to buy a real tool. The Starrett auto punch is definitely well made and feels good to hold, and operates smoothly -- but it doesnt do much. Im getting just a tiny nick in 24ga steel sheet metal, and not much better in 1/8 aluminum extrusions. This is at the highest setting. I guess this punch is only really intended for softer materials, but that wasnt super clear to me in the description. Im just a weekend warrior and not familiar with the intricacies of selecting proper fabrication tools. Evidently I I was also surprised by how small it is...the dimensions are clearly given but I have small hands so figured it wouldnt be an issue. I can hold it fine but it gets lost in the pencil-loop of my toolbelt where I kept my old one -- I have to take off my gloves and poke around in there to fish it out, which isnt much of a time-savings. Im returning the punch in favor of the full-sized 18C, which apparently is more like what Im looking for.

-

Dave K.

> 24 hourAfter just a few uses, stopped resetting after punch. Springs seemed to be worn even when new. Internal pin seemed to wedge in body. Could be a knock-off and not a real Starett.

-

Leonard Gump

> 24 hourThis is the second one Ive owned. The first keeps disappearing on me. Now I KNOW where I can find one when I need it. Being Starrett, you know its high quality.