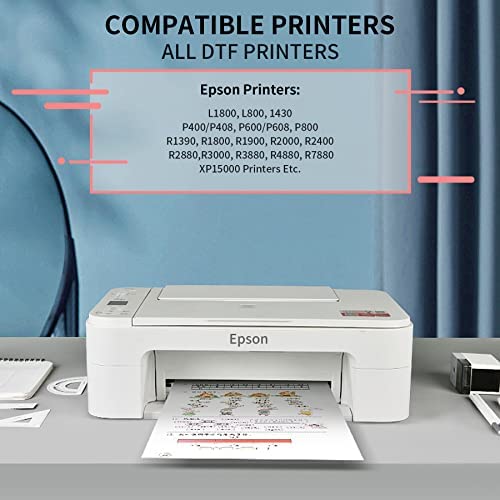

Welacer DTF Ink Premium 6x100ml Heat Transfer Ink Conversion Kit Refill for Epson L1800, R2400, L800, 1430, P400,P800,R2000,XP-15000 All DTF Printers,for DTF Film(White Cyan Magenta Yellow Black)

-

Frances Rodriguez

Greater than one weekThe ink itself is great. But they come in small bottles it’s not enough for the price that we are paying. It only comes in 100ml. They don’t have an option for a larger amount. Just go with other inks that offer more options. Overall like I said good ink not worth the price.

-

krista felix

> 3 dayI wanted to try this product to be able to sublimate on to cotton material. So far all images I print the printer roller runs through the ink and makes lines through the image. You also need to get DTF powder to use this paper. It is hard to tell what side is the side you print on, would be nice if it was clearly marked.

-

Christina

> 3 dayThese sheets do what theyre supposed to. But the sheets are obviously cut to size. Each sheet is a different size and uneven

-

Jerald Hoppe

> 3 dayDoes a great job

-

Cookie

> 3 dayAwsome product this the only brand I purchase it never let me down with the beautiful colors it produces with of course my great dye ink so the combination is like 2 peas in a pot together

-

Chris

> 3 dayI use this film with the sublimation hack. Works perfectly and goes through my Epson printer with no problems. The price is great.

-

TiciaLove

> 3 dayI used this in a Sawgrass SG500. The product itself is really good. However, this product did not come in the packaging that is shown. Also, I have noticed that many of the sheets are different sizes. I have had to trim a few pieces because the sizing is off. It is a great price for the quality and quantity that you get.

-

Linn

> 3 dayThis product works, but I have to apply it as soon as it prints because once the ink dries to a certain point this no longer sticks well. It could be a combination of the sublimation paper and ink that I use as well as this product. It works perfectly as long as I apply it right away. I would buy again

-

Virginia Diop

> 3 dayWorks as expected

-

Cricuting with Delonda

> 3 dayIts so hard to tell which side is the right side and it is easy to waste materials by printing on the wrong side.