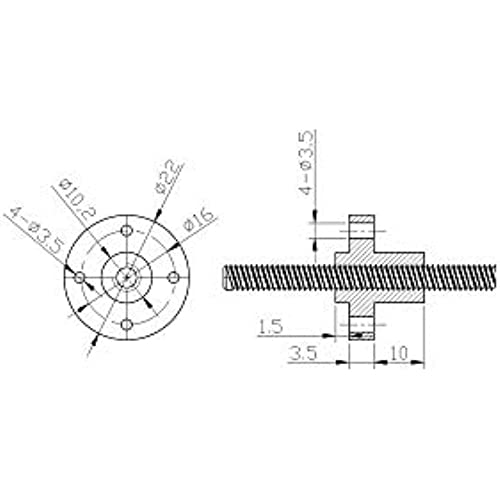

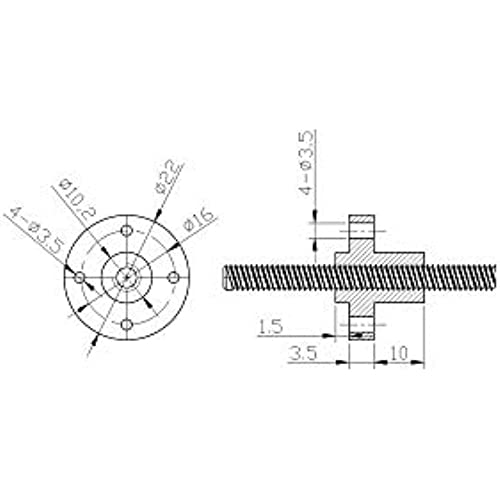

Befenybay 6PCS Diameter 8mm Black TR8x2 Lead Screw Nut for CNC and 3D Printer Parts (Size: Tr8x2)

-

Kitzune

> 24 hourVery solid and tight threads. Barely any play along the t8 rod. No lubrication needed and very quiet in operation. I have known delrin to be a very strong polymer - not easy at all to wear and cut but using this material makes the most sense to make contact with metal.

-

Erick

> 24 hourMy ender 5 plus was driving me insane till I used these. Its so much better now, no more squeaks!

-

J.G.

> 24 hourTight fit, no slop, perfect for my needs

-

QUANG D.

> 24 hourGood item

-

Paul

> 24 hourSuper quiet, barely any play compared to brass nuts. These fit my 3d printer perfectly. Z movement is not loud at all. I hear the motors themselves way more clearly over the lewdscrew nut.

-

MichaelM

> 24 hourI used these to replace the worn brass lead screw nuts on my Anycubic Mega X. They are perfect fits, and a little quieter than the originals. I do recommend that you put some lube on the lead screws to minimize wear, but that would be for nay lead screw nuts.

-

Door Maker

> 24 hourWorked!

-

Roald

> 24 hourEnder 5 plus is no longer squeeking after installing this.

-

Ama Customs

> 24 hourIt didnt make my machine as super quiet as i was hoping (i have another rail somewhere thats causing some buzzing/squeaking noises), but they did quiet it down a bit, and i feel like everything is actually running more smooth. Never used the plastic nuts before, but i dont think id go back to brass now

-

Arthur A. Haglund

> 24 hourI decided not to wait for the brass ones to wear out. sure they are self-lubricating, as they wear out, but their wear provokes the increasing possibility of backlash on a gravity-engaged moving part. These POM pieces are the worlds slipperiest plastic with the best wear rate. They are a tight fit, compared to even new brass lead screw nuts, but that tightness is not binding. reassuring is the word I would use. From what I have read, the wear properties are much superior to the brass. I retain the brass as they have not been used to the point of being worn out. The Z gantry of my 3D printer feels more substantially connected and any crew-induced motion artifacts no longer exist. Just smooth layer lines, buttery smooth and consistent. This will be a first order upgrade for any and all of my new FDM printers from now on.