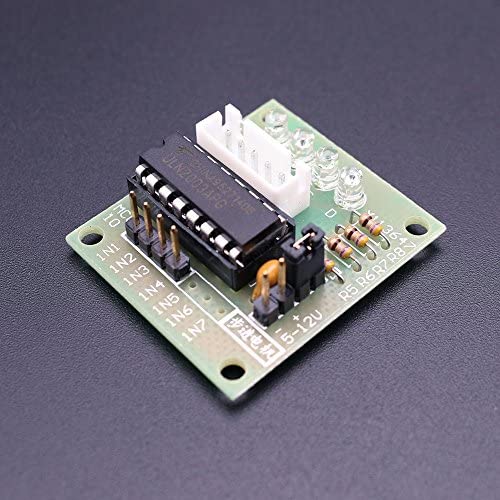

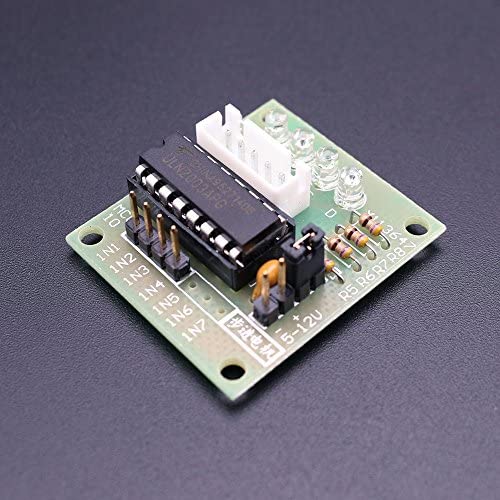

ELEGOO 5 Sets 28BYJ-48 ULN2003 5V Stepper Motor + ULN2003 Driver Board Compatible with Arduino

-

L. Wallace

> 3 dayI will be using these motors for self stirring cauldrons for a Harry Potter fair.

-

Rebecca Zhou

Greater than one weekGreat product with reasonable price!

-

Donald Beatty

> 3 dayGreat stepper motors for learning to control steppers with an Arduino. Inexpensive, plenty of torque and decent (though a little slow) speed. they seem to be accurate enough and repeat without any noticeable slipping. They require 32 steps to get the internal rotor to make a full revolution, and the rotor is geared down 64:1 to the rotation of the outer shaft. That means if youre using the stepper.h control from the Arduino library it will require you to enter a value 2048 in the number of steps line in order to get one full revolution of the outer shaft. And at least for the motors I received, 15 RPM seems to be about the maximum I can get out of them. They do run a little hot, but not excessive. Power them with a separate (not the Arduino power) 5V DC power supply and they work great.

-

RadarRon

> 3 dayAs advertised, nothing really to say about it good or bad

-

james price

> 3 dayGood price

-

Jordan L.

> 3 dayFor the low price you wouldnt expect high quality stepper motors and drivers. However these perform amazingly well in both torque and accuracy for their price and size. I was hesitant at first but am happy with my purchase and would buy again. They do tend to heat up after extended use or with heavier loads, however for most applications of stepper motors this isnt a problem. If you are looking at these and wanting high speed rotation & long continuos running then a regular DC 5-9v motor would better suit you. Which is what these will provide you. They dont spin fast looking at the external shaft rotation however the inner gears & 4 phases allow you to use multiple step types depending on your need. Including wave step driving with each phase cycling one on at a time giving the simplest controlled rotation for beginners. Or full step using two of four phases on at a time for highest torque. Or Half step using a mix of two phases of full step with one phase alone in between, to give highly accurate movements with medium torque. The only suggestions I would have is buy or setup a separate dc power supply for these as the arduino or other micro controllers wont have the volts and mA that you need. Also if youre a beginner or new to arduino or micro controllers or stepper motors this is for you it is simple to set up, no soldering, no prior stepper knowledge required; just plug in motor to driver, hook up all four driver digital input pins to a micro controllers digital output (like arduino, raspberry pi, etc) plug ground and power cables to relating micro controller pins or seperate power supply pins and youre done. All thats left is running a code thru micro controller. I will note however that you will need more male to female cables if you plan to hook up more than 2 stepper drivers to micro controller; Good for both experienced users for projects/fun and good for beginners who are learning about steppers or just getting started, the LED lights are beneficial for troubleshooting and making sure your code works properly. I took one of the steppers apart. Taken apart theres Aluminum casing outer shell, 1 layer of 8 teeth on casing bottom & 3 layers of 8 teeth each interspersed inside center hole of the coil plastic rings sitting on top of first teeth layer, giving you 4 layers/phases & 32 teeth total or 32 steps. Both coils are wrapped around plastic rings and sealed. Soldering on steppers and drivers look & feel solid. First coils ends being the yellow and blue wires respectively. But being unipolar the center of the coil is also connected by center tap to red wire. Bottom coil is same with ends being orange and pink, center wires are connected between both coils into single red wire. The rotor is plastic with a permanent magnet surrounding it, the rotor shaft has 9 teeth. That shaft extends up to top plate that has 3 ganged gears plus the gear for external gear shaft. All these together do infact give you a 64:1 ratio where 64 rotations of the rotor = 1 rotation of the external gear shaft. Note that one rotation of the rotor requires the 4 phases 32 steps to make one full rotor rotation. So a lot of rpm is needed to give you even 10rpm of the external shaft. This is where torque is created and heat is generated, Seems solidify enough built for its power rating and most stepper uses, mechanically the gears are setup for best possible torque

-

Ming siu chan

> 3 dayI like this product, due to its price is very affordable.

-

Jesse G.

Greater than one weekYeah, bought these... not really looking into the details. They are VERY SLOW. Too slow for my application. I can stop the shaft with my fingers, so no real torque either.

-

David C.

> 3 dayExactly as advertised, with high quality motors. Less expensive than buying the 28BYJ-48 unipolar steppers and ULN2003 drivers separately. Add to this that Elegoo is a reliable vendor and it is a perfect combination.

-

FRANKIE D.

> 3 daythis i also got for a friend,and he love it !