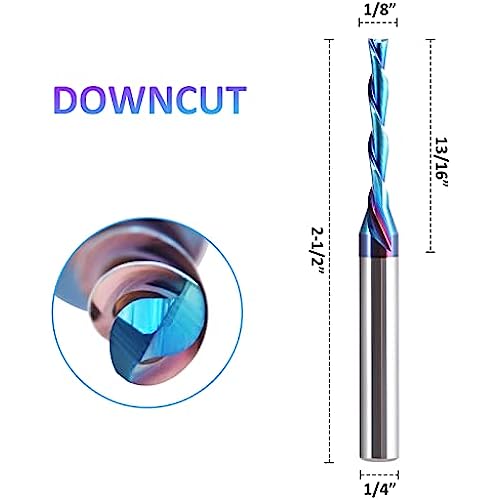

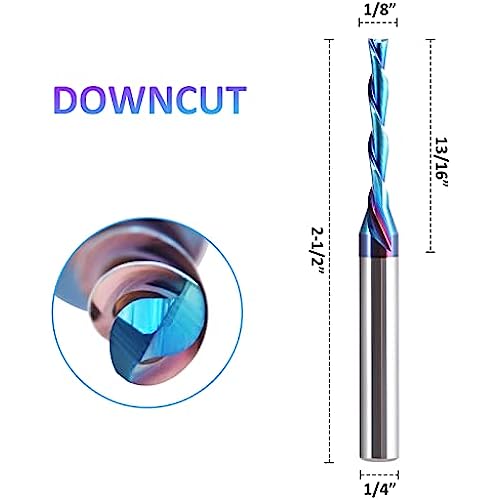

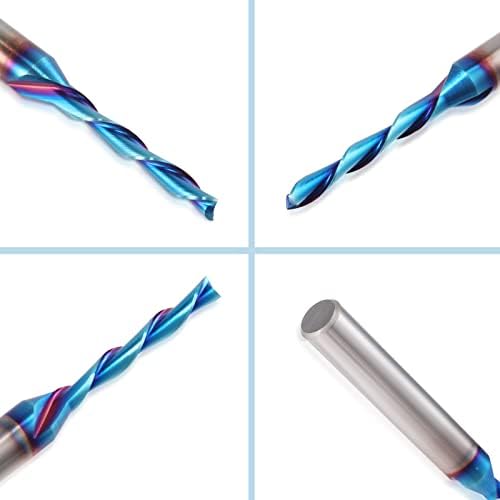

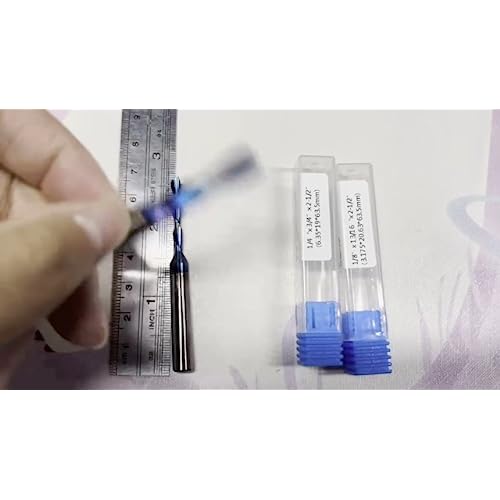

HQMaster Spiral Router Bits Down Cut 1/4 inch Shank Solid Carbide Nano Blue Coated Spiral Downcut CNC Bits End Mill for Wood Cut Carving Engraver (1/8 Cutting Diameter)

-

Humphrey-Tech

> 24 hourIve been using this bit in my wooden sign making business and so far it works great and has remained sharp. Ive used it for 3d roughing passes in hardwood and in other applications where a ballnose bit is useful. So far, I havent noticed much difference in the quality of cuts from my more expensive bits. Its amazing to me that you can get quality tooling these days at this price point. These bits would make a great go to bit for production without having to stop to resharpen tooling. I would definitely recommend, and will order more!

-

Uhhhhhhhhyeah

> 24 hourSkip it, buy a higher quality bit and save the headache.

-

EnigmaDan

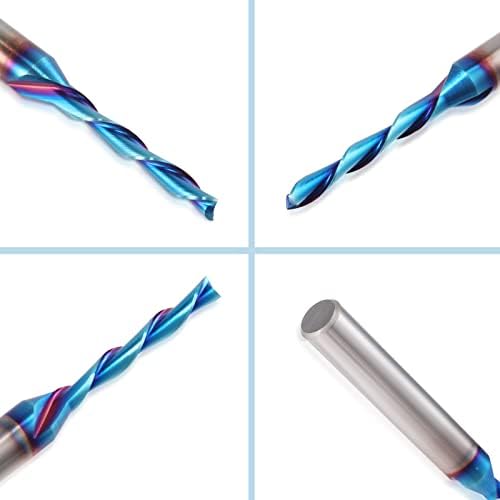

> 24 hourI made a test cut with this bit on a piece of Gaboon Ebony to see how it fared. It cut clean and held its edge even on that brutal wood, albeit I only ran about 12in/305mm. Being coated carbide, I expect that itll hold up well if it made it through that first run without immediate dulling. As with any router bit, RPM and feed speed are critical in getting the best results. I ran this at 25,000 rpm on my router table and fed the workpiece by hand, feeling for the proper speed. Only experience can guide you if youre feeding it by hand. If youre fortunate enough to have a CNC, follow the appropriate guidelines for the material youre cutting for best results.

-

paradug

> 24 hourHQMaster’s 1/8-inch carbide ball nose end mill with nano blue coating and 1/4-shaft is a well-made and sharp bit. The nano blue coating improves the heat performance of the bit, and the 1/4-shaft adds rigidity. Both features will increase the life of the end mill. The bit comes packaged in a typical rectangular plastic box. The bit itself comes without any markings on it shaft. I much prefer that the end mill be labelled to allow easy identification and to prevent tool mix-ups. This is a good workhorse type end mill that I will find a lot of use for.

-

Robot Power

> 24 hourThis cutter is dimensionally accurate according to my caliper. That is good as sometimes 6mm shank are sold as 1/4 (6.35mm). Under magnification the ball end is smooth without burrs. It is only 2-flute so I wouldnt try to cut metal with it but wood and plastic should be fine.

-

AndySki

> 24 hourIm still kind of a newbie in the CNC Router arena, and while learning how to use the software thats needed to work with these machines, I am gradually building up my arsenal of bits so I can effectively use the machine. One thing I look for is bits that are made of solid carbide. They just keep their sharpness longer than high speed steel bits, so they run cooler and smoother longer. I also try to get bits that have a coating over the cutting area of the bits, as this also contribute to longer life and smoother cutting. I used this HQMaster 1/4 inch shank 1/8 inch cutting Ball Nose End Mill today as I was experimenting with 3-D carving. I created a simple half-torus model that I intended to carve, but was running into problems with the machine plunging deep into the wood before starting to carve the shape. It was supposed to start at the surface, but started probably 10 or 15 mm BELOW the surface instead. I never did figure out why it was doing this, and after a long period of trying I have up for the time being. BUT...I was amazed that this HGMaster bit still cut smoothly and evenly despite the fact that it was being forced to carve from a much deeper depth than it was supposed to. I let the program run a few minutes at this wrong depth before I shut it down, and observed the edges of the cuts - they were perfect, really nice and clean. Thats a great testament to the quality of this bit. Most bits can cut well when the machine isnt trying to power through a cut thats outside of its design parameters, but it takes a special one to be able to deal with it and do a good job anyway. Recommended!

-

Fox Workshop

> 24 hourWorked well even with a very high feed rate and stepover of about half the width using the entirety of the flute for quick roughing. Ran it for about 8 hours so far and it still feels very sharp.

-

Ray Rauch

> 24 hourThe quality is fantastic and I use 1/4 more than any other and do tend to wear on them. These hold an edge well and have been put to great use cranking out holiday gifts. I cant think of an argument to pay more when this quality stands up to other really expensive options Ive tried. Update: This bit continues to hold an edge well after dozens of operations through hardwood at pretty aggressive settings of speeds. These are a fantastic workhorse bit to use.

-

RobWC

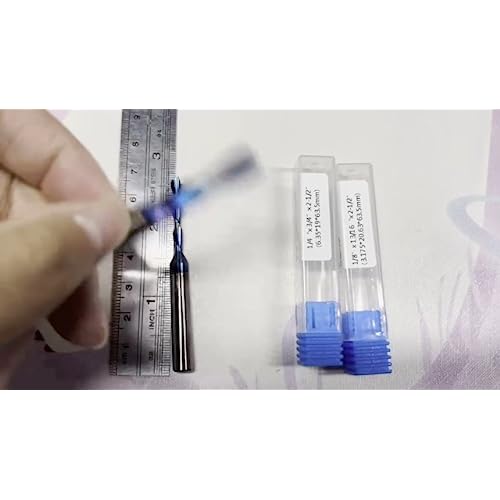

> 24 hourI bought the 1/8” cutting diameter bit, and used it with my router and DIY circle jig to cut a perfect, 11” diameter circle in 1/2” plywood. The down cut left no splinters on the top side of the plywood, and very few on the bottom side. I do not know how long it will last, but it worked very well on its maiden voyage.

-

Fredco

> 24 hourWhile I would prefer a bearing bit (and I ordered one) this bit came within a few days of order and worked just fine for my needs. I needed to duplicate some Plexiglass objects and so set up the bit to travel along the original and cut the part out. My concern was burning the original (without having a bearing guide) but that was not the case and given the correct speed and movement speed this bit worked like a champ and stayed sharp for the duration of my project. I was cutting 1/4 Plexi and while I thought heat might be a problem it seemed to work just fine