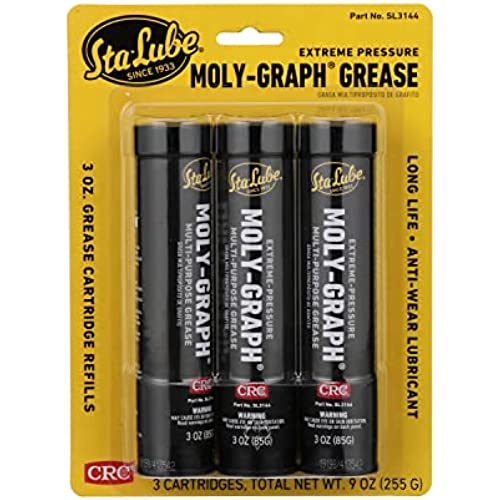

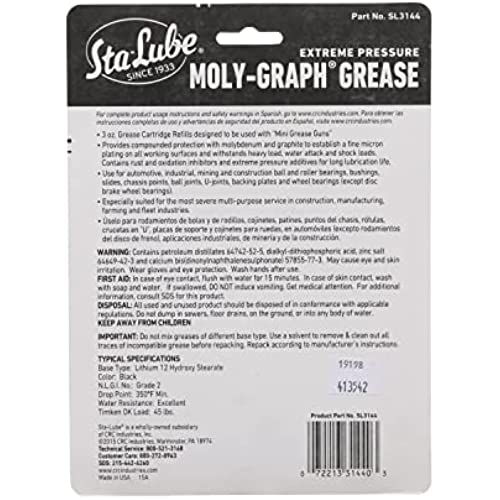

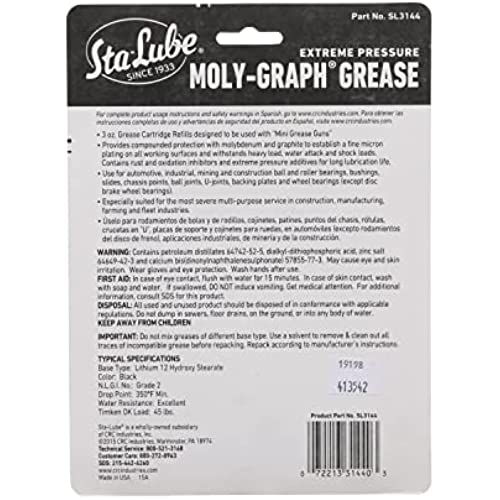

Sta-Lube Moly-Graph Extreme Pressure Multi-Purpose Grease SL3144 - [Pack of 3] 3 Wt Oz., Extreme Pressure, Multi-Purpose Molybdenum and Graphite Grease

-

Robert E. Hodge

> 3 dayBeen using this grease for over 35 yrs and it has Never cost me a wheel bearing or a u-joint either.

-

Jacinto White

> 3 dayGood grease I used it on my trailer and hitch.

-

D. Quatrini

> 3 dayNot sure how to review grease, but I did use the moly cartridge on a newly installed tie rod. Consistency seems good and I dont expect it will easily wash out on exposed applications like brake caliper slide bolts.

-

Dog Lover

Greater than one weekI havent actually used it yet, except to lube the grease gun itself. But one of the tubes was only half full. It had 3 of grease in the 6 tube. The other two had 5 of grease.

-

Mr. B

Greater than one weekWeighed all 3, all within a half of a gram of each other. Loaded one up in the gun and ready to go. What more can you ask for?

-

bigal

> 3 dayGood price on grease

-

Joe D

> 3 dayI lubricated my rv chassis with this product. Worked perfectly

-

mchees

> 3 dayIts grease - it works great. What else can you say about grease? My application was nothing high pressure or temperature so it works just fine.

-

John

Greater than one weekIts a huge tub of moly grease, bigger than youd expect. Just buy it already.

-

Jesse S

Greater than one weekI was looking for a substitute for the Lubriplate Mag-1 grease thats recommended for my Toro snowblower auger gearcase. The Mag-1 grease is expensive and hard to find locally. I found this CRC Moly-Graph grease to be a good substitute. One concern I had was that some extreme pressure greases contain sulfur compounds that will attack the copper in the bronze worm gears in snowblower auger gearcases. I called the CRC technical hotline, but they had no test data on compatibility with copper. So I ran my own informal copper compatibility test following the protocol of ASTM D130. I took a strip of clean polished copper, coated it in CRC Moly-Graph, and heated it over a boiling water bath at 100 Centigrade (212 Farenheit) for 3 hours. To my surprise, after 3 hours, the copper showed zero--and I mean zero--visual evidence of tarnishing or corrosion. It was better than the 1a visual reference strip in the ASTM D130 protocol. My conclusion is that the CRC Moly-Graph is very compatible with copper, and therefore will not damage the bronze worm gears in snowblower auger gearcases. However, when switching from a different lubricant to the CRC Moly-Graph, its important to flush out the old lube and get all the old stuff out with brake cleaner, so that any potentially incompatible materials in the old grease/lube dont contaminate the new CRC Moly-Graph. Another benefit of using grease instead of oil in an auger gearbox is that it wont leak past worn seals. However, it can be hard to get the grease into the gearbox. I use a large turkey brine injector syringe (not a baster, a syringe) and use it to inject the CRC Moly-Graph grease into the auger gearbox.