Up Down Compression Spiral Flush Trim Router Bit, 1/4 Inch Shank Solid Carbide Flush Trim Router Bits CNC Spiral Bit with Nano Coating by EANOSIC

-

Mr. Stanton Mraz

> 3 dayUnreal quality for a great price. Leaves a great edge finish. No tear out or splinter. This is the 3rd brand of compression spiral I have tried and this one is far superior from the others. Used for several projects and havent seen any decline in the performance. Definitely recommend this product.

-

Ronald Russell

03-06-2025I have a couple of bits from this company, and I’m impressed with the quality. This particular 1/4” bottom bearing flush cut bit is a useful size for following tight patterns or for trimming flush to another piece. You do need to make sure your pattern is accurate and smooth as any imperfections will show, given the small bearing diameter. I’d consider this a tool for precision work, rather than hogging out the edges of countertops- solid carbide is not for forcing, and the 1/4” diameter means you need to take it slow. If you have never experienced the improved quality of cut from a good spiral ground router bit, you should give this a try.

-

AminA

> 3 dayI am giving this particular bit 3 stars, because it could have been a rare manufacturing flaw. I used it on a 1 inch cherry wood removing about 1 to 2 mm, and after about 5 minutes and 2 feet it fell apart. Luckily I had an upcut bit by the same manufacturer that I used to finish the work. The other bit performed perfectly.

-

Shaun King

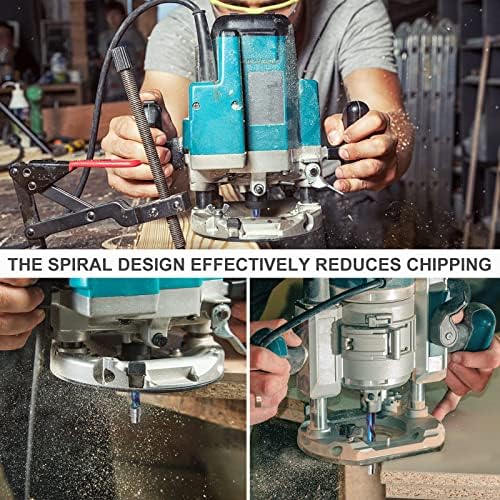

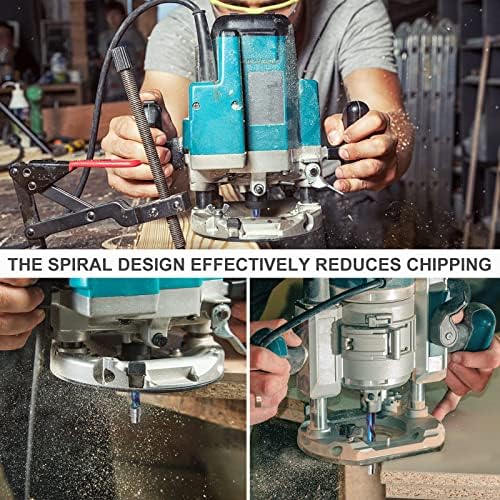

> 3 dayThis bit is only used to produce repeatable results using a pattern attached to the workpiece as a guide. A bearing is used to follow the pattern and neither the process or this type of router bit are anything new. What sets this bit apart is that it cutting edges are slightly angled to slice both up and down. This results in a shearing cut rather than a chipping cut and should produce a smooth cut with little or no chip-out - well see. This is also a small diameter bit. Itll get into tighter areas, but its small size requires a bit more time and patience. You cant force this bit because its cutting tip speed is much slower than a bit of larger diameter. Both rotate at the same RPM, but the larger bit has to move faster around a larger circumstance. This little bit has the potential to produce edges ready for finish, but you cant rush it. Its also important to rough-cut work pieces very close to their finished size because you cant hog material with bits as small as this. This bit is for the last 1/8 give or take, youre not going to plow with it, at least not very far before it breaks from heat buildup. Use it as intended and with care and it shouldnt disappoint.

-

Val Anne Welch

> 3 dayThis is my first experience with an up down compression spiral flush bit. It did not disappoint. So far, I’ve only used it in testing and one small project, but the results have been very encouraging. Plywood trims were clean with no significant chipping. Softwoods like fir and cedar trimmed clean and smooth. I used it with my trim router and, as another reviewer has stated, a larger base would be helpful. I did get a few waves but that was entirely due to my too-casual technique at the time. Key unresolved issue is longevity of the product. So far I’ve seen no red flags in that regard and expect this bit to serve my purposes for many years to come. If that should change, I will update my review.

-

Corey

> 3 dayThis bit is 1/4 from head to toe. So the bearing is also 1/4. Ive never seen one this small. Who knows how long it will last? Ill update if there are any problems. The blue coating and/or the flute design makes this bit cut very clean! For the few materials I tried, there were no blowouts or chads left hanging on top or bottom! I didnt have any kind of chatter or wobbling that I expected. However with the tiny bearing diameter, it will definitely transfer smaller imperfections from your template to the workpiece. More so than with a 1/2 bearing. This is just a lot easier to work with. I think youll have to be careful not to rely on bit color to tell you when youre making too much heat. You wont see discoloration on this coating. I guess youd have already made way too much heat if your bit was bluing. Best to keep your pass speed under control anyway.

-

Buddys Dad

> 3 dayA spiral flush-trim bit such as this is a somewhat newish design that combines features and benefits of both upcut bits and downcut bits. And flush trim means that this bit is designed to follow a pattern along its bearing, to allow the material above the pattern to be cut flush to that pattern. You don’t want to ask a bit such as this to hog off much material; it’s forte is trimming small amounts smoothly even with sheet goods and areas of changing grain direction. So use your saw to cut close to the line, and this bit to just make that last 1/16” tight to the line and smooth. I can’t say that I have past experience with this company, but this bit does a nice job for a very good price and I would buy one of these again. I’ll update this if the bit seems to not hold up well! I hope this review has been helpful to you!

-

simonbw

Greater than one weekThis seems like a decent flush trim bit. The compression pattern does a decent job of making a tear-out-free cut on both the top and bottom of your workpiece. My main complaint with this is that the bearing seems a bit undersized, so if you have the cutting edge overlapping your template at all, it will cut a bit into the template, and it also leaves your workpiece ever-so-slightly undersized. Its only a slight annoyance, but its one I havent had with name brand (i.e. whiteside) router bits.

-

Woodworx

> 3 dayBit works great, stays sharp

-

George BIII

> 3 dayThe good thing about this bit, is it is small. I used it with a template with a lot of tight corners and grooves. It did well getting into the small recesses. very little work after wards. Because the shank is 1/4 and the bit is 1/4, there was a little chatter when it was grabbing the grain and would jerk the wood and gouge. I did use very small passes with this, because I had to use smaller passes to prevent the chatter and for safety to of course. If you think about it, a safe pass is less than 1/2 the bit, if not 1/3 and less of the bit. if this is a 1/4 bit, then you should only take 1/16 off on each pass. I think if I was going to use this again, i would use a larger bit to take most of the material, then use this bit to get into the intricate places.