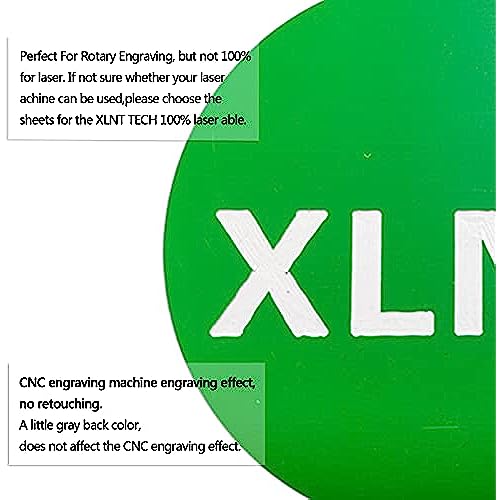

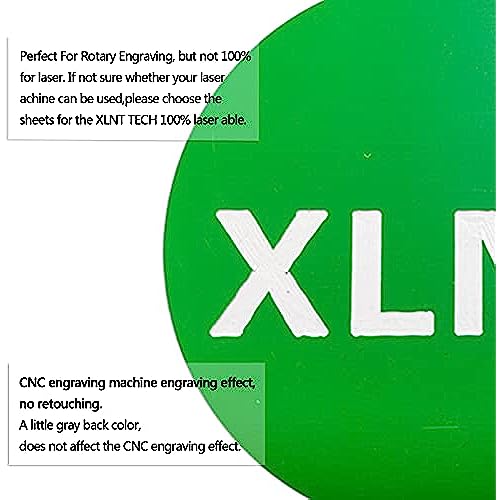

XLNT TECH Engraving Double Color Sheet (7 x 11“ x .040”, 12 Pieces & 12 Colors) for Interior Signs, Badges.

-

Frank Epstein

> 24 hourI paid for .06 and got .04 thickness. Item Not As Described. returned. They are, however, easy to to do the score and bend to snap into smaller pieces. take a flat edge like a metal ruler, carefully gently slide the edge of a box cutter to score, or use something like a manual slide the blade thing with mounted blade, about 10 times to make a groove, bend it against an edge to break, snapping into smaller pieces, then use a knife to trim the edges if any bits are sticking out.

-

PiperGeorge

> 24 hourWorks good. Easy to cut. Got the variety pack and will probably buy more.

-

Violetta

> 24 hourThis company if very deceiving. Why would you label something laser EVERYWHERE and advertise as laser material knowing it will not work in a laser machine. Melted and melted into my $6,000 machine. Way to go! Will never buy from this company again.

-

queenidog

> 24 hourI was disappointed when I got my order. The description implies that thtere are 12 colors/12 pieces, so I was expecting one piece of each color. I didnt even have a choice of color (hence the reason I thought I was getting all colors). I got all red panels, 12 of them. Doesnt work well with laser engraver.

-

Jonas Bauch

> 24 hourI generally get good results with my Epilog laser engraver but this just didnt come out well. Highly sensitive to focus, but even then I had dark gray shadow lines. My signs didnt come out well and I do wish Id looked elsewhere

-

Glenn P.

> 24 hourI feel bad for this line of products getting all these negative reviews because people havent dialed in their settings. Ill admit that it took me 4 or 5 tries to get it perfect, but Im getting consistent results now. I use an Endurance 10W diode laser on an Openbuilds ACRO platform. Doing the cuts in 6 passes yielded the nicest edges, but with different air assist setups Im sure some more aggressive cutting could be done. I dont use air assist for the engraving portion and definitely do use air assist for the cuts. Alcohol does a great job wiping off any charred dust the might get blown around. So there ya go, 5 stars from me.

-

T. Laynor

> 24 hourPurchased this as it came with various colors and said it was LASER engravable. Normally the top layer will cleanly vaporize with LASER application, but in this instance it melted and the surface finish was pebbly, not smooth. Tried various power settings, but did not achieve a smooth, clean engrave. This maybe a rotary-only engravable product.

-

Brent

> 24 hourAs a new hobbiest I didnt really know what I was doing. When I purchased this product I didnt know I really the gem I found. This is a great product and at this price point it allows hobbiest to experiment and get better at the craft.

-

Benjamin J. Coleman

> 24 hourTried engraving it, it caught fire. I ended up having to throw my engraver out the window. It destroyed my engraver and the shirt I was wearing.

-

Michael Rivera

> 24 hourSays its laserable, but all my research says it emits poisonous gas when lasered