XLNT TECH Engraving Double Color Sheet (7 x 11“ x .040”, 12 Pieces & 12 Colors) for Interior Signs, Badges.

-

Jason Sanderson

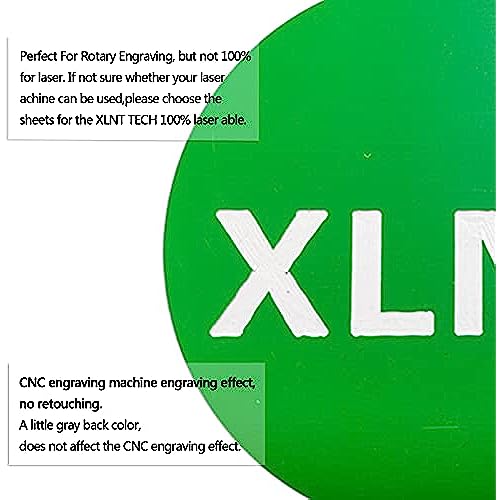

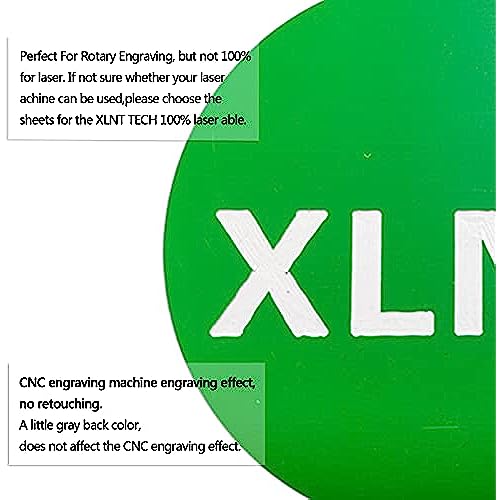

> 24 hourGreat product for CNC engraving. This product is not good for laser engraving

-

Andy Canable

> 24 hourHavent got to use them yet but they look fine!

-

Placeholder

> 24 hourGood quality.

-

abosoxfaniam

> 24 hourProduct seemed good for making name plates, but end up subpar. When using my CNC machine to engrave nameplates, I had a bunch of issues with the top layer not cutting clean. I spent a lot of time going through with a scribe trying to get the black top layer to break free. This product is not a poured plastic topcoat, but more of a laminate on top. Pretty much a waste of my money for what I am trying to do. I was expecting clean cuts, but the top was like a layer of tape that did not want to cut clean.

-

creighta

> 24 hourDO NOT BUY!! Not a laser friendly product as advertised. In the lowest power settings, my 40w burns this material and the fumes smell like PVC which is not safe for laser operation.

-

jen

> 24 hourUsing for laser etching, works great

-

John

> 24 hourBig mistake Item said bright white and we got red / grey. Our staff printed it. Inspector failed us immediately and went no further. We will reprint all the signs again with other material and call then inspector again and have all parties standing by, again. Expensive! Thanks for the bad description or wrong product sent; do not purchase.

-

Gary Holtz

> 24 hourVery low quality. Dont waste your money

-

Christine Margaux

> 24 hourThis engraving plastic works as well in my laser as any other I have tried. It comes with a plastic protective film on top. You want to leave that film on when you cut and then carefully remove it afterwards as it will keep your material from getting all sooted up. Raster engraving will not leave a smooth surface. Ive tried the stuff from Trotec laser and I didnt get a smooth raster finish with that either. What does work is cutting, and its cousin - vector engraving (which is just cutting, but with less power and faster so it doesnt go through). The top coat on engraving plastic is REAL thin, so youll likely find that the fastest movement and the lowest power your laser will do will be enough to leave marks. THE MOST IMPORT THING IS SAFETY!! I run a Middle School makerspace. The most important part of onboard training (Which i do for each and every tool in the space, for each and every student that comes in) is how to work with a tool safely. Lasers work by cutting things with heat, so a risk with laser cutting is always FIRE. Ive had fires start when cutting cardboard, paper, foamcore, and rubber. You should ALWAYS have a fire extinguisher next to your laser cutter. You should always check before you start cutting that you know where said extinguisher is. You should NEVER leave the laser while its running. Watch it work! Also, you might keep a spray bottle full of water near the laser. Most laser fires can be extinguished with a few swirts of water and thats a lot easier to clean up than a fire extinguisher. You will need the following upgrades on your laser to use this material: 1) FUME EXHAUST: Folks, having an exhaust to take your fumes outside is super important no matter what you are cutting in the laser. Cutting WOOD in the laser results in ultrafine (<2.5pm) particles that are hazardous to your health. This stuff is ABS plastic, read up on burning ABS - it will release formaldehyde which is REAALLY bad for you! Dont skimp out, get a fume exhaust system in place. 2) Air assist: ABS is known to be a fire-prone material when laser cutting. Having an air assist is really important for blowing out most fires that will start when cutting this material. Again, dont cheap out, an air assist costs less than a new laser cutter or house.

-

PiperGeorge

> 24 hourWorks good. Easy to cut. Got the variety pack and will probably buy more.