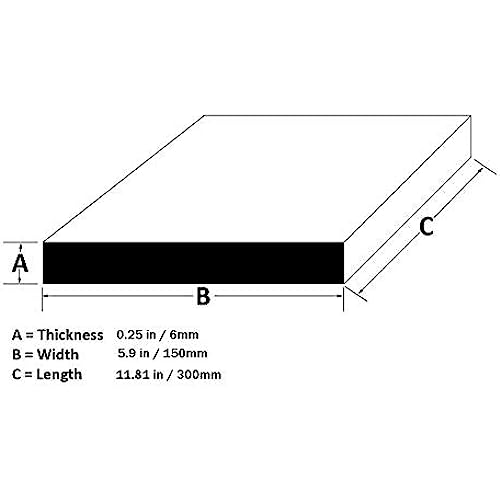

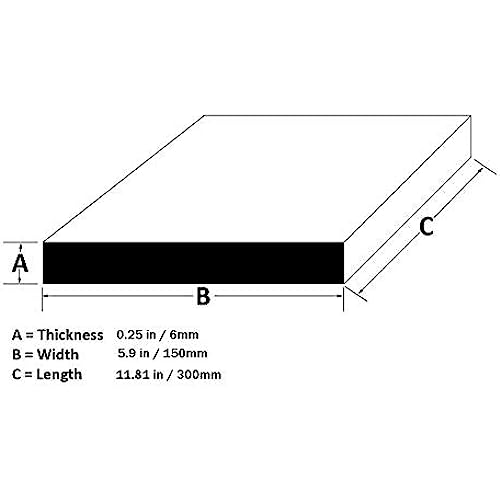

1/4 Inch 6x12 Aluminum Sheet 6061-T6 Aluminum Tooling Flat Sheet Plate Bar Mill Stock

-

isaacmooney

> 3 dayUse - used as a scabbard for my boat. (It’s like the Rudder for the boat/ protects the prop from rocks) Metal held up well, minor scrapes from my adventures on the waters and the summer droughts changing water depth. Welded well and has no cracking on the weld line.

-

Robert Groff

> 3 dayI used these plates to mount rod holders on my boat. They are the perfect size.

-

Best Customer

Greater than one weekThis worked great to add very strong plates to secure my boats stanchions and cleats. Easy to cut and shape.

-

Josh B.

> 3 dayits about 11 13/16x 5 15/16/ But close enough just have to adjust some measurements

-

Russell

Greater than one weekgood quality as advertised

-

Prof. Sanford Gleason

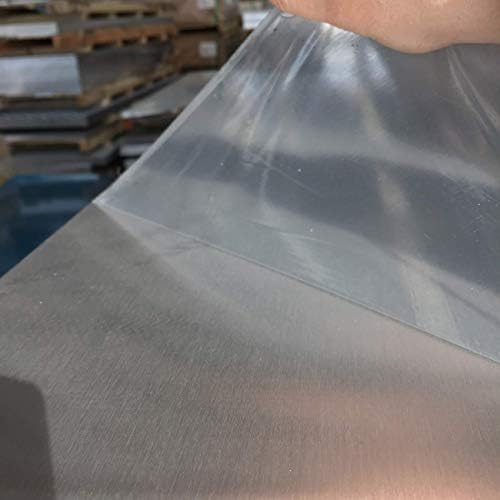

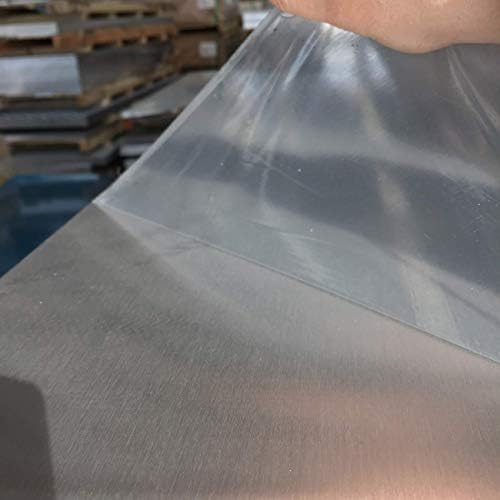

> 3 dayI ordered 1/4 Inch 6x12 Aluminum Sheet 6061-T6 Aluminum Tooling Flat Sheet Plate Bar Mill Stock KAYLAN. Everything I hoped for. Good quality. Flat. Well machined. Even came with a protective skin.

-

Steven Auletto

> 3 dayProtected and very well packed. Nice cuts and perfect size. Flawless .

-

ollim, aka doc smith

> 3 dayA solid chunk of aluminium! Works great as a heat sink for my hotspot!

-

Eric

> 3 dayItem as described. Thats all you can really ask for when ordering a chunk of metal! I made heel plates for my motorcycle with it.

-

Kennith Edwards

> 3 dayPurchased to make EGR block off plates for a 440 big block and a 1750 VW. High quality aluminum plate, great density and easy to work.