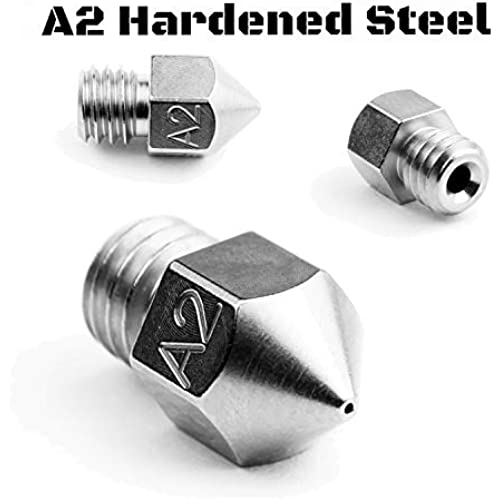

Micro Swiss MK8 Plated A2 Tool Steel Wear Resistant Nozzle (MakerBot, CraftBot, Creality, CR10, Ender 3, Ender 5, Tevo Tornado) .4mm

-

wmcksmith

> 24 hourI am on my second one of these nozzles. I dont think that the first one had to be replaced but I was doing some maintenance so I changed it. The first one lasted me at least 6 months with hundreds of hours of printing with no problems. They are a little pricey compared to regular brass nozzles but youre limited to what you can use with the micro Swiss hot ends. At least they last a while.

-

Timothy

> 24 hourI original got this nozzle for my ender 3. The nozzle works well, material doesnt clump up on nozzle as much and it handles abrasive filaments well. One thing I had to do was turn up the temperature for PLA filament by about 10°C to get the plastic to flow consistently.

-

Tristan L

> 24 hourThis nozzle is easy to clean, has a true .4mm opening, and is durable. Ive printed carbon fiber PLA with no noticeable change in performance and it prints out all the PLA prints with good filament perfectly. I would recommend to someone wanting an easy to service nozzle. Glad I purchased it.

-

Alexandria Kuphal

> 24 hourThe nozzle is slightly longer than most, so I had to add a washer to my cr touch to get it to work properly. Also had to tweak my temps and retraction setting to adjust for the extra length. After that, the nozzle worked perfectly, prints look great.

-

The Lord is my Shepherd

> 24 hourI have a couple of spools of Luminescent Blue filament and a spool and a half of Carbon Fiber. Im told these filaments can wear out a brass nozzle in a single print so I needed something more durable. Tungsten nozzles were out of stock for a while, and the hardened steel nozzles were rated almost as tough, so I ordered and installed this on my Ender 3 Pro. I read online the process for swapping out a nozzle and gave it a go. No leaks, and prints come out fine.

-

Greg

> 24 hourSo I had the unfortunate opportunity to break my beloved M-S nozzle (my mistake, tried to remove it while cold after a PETG print and sheared it off) and because I was in a time crunch, replaced it and the heat block with a cheap backup I had lying around. The difference is night and day. I had nothing but globs and print failures until I bit the bullet and ponied up the $25 to get a new M-S nozzle and heat block. Problems entirely solved! Printing PETG and PLA like a champ again on my Ender-5 with M-S direct extrusion. I also use the 0.8mm nozzle from M-S for TPU in this setup, and it works flawlessly. (side note - I also got the Sunlu filament dryer and it solved my PETG stringing issues. It makes a great companion to this excellent nozzle system) Micro-Swisss sticker has earned its place on my tool cart!

-

Rodrigo Sosa

> 24 hourI received an used nozzle, it has filament remanents on it. Not sure how this can happen.

-

Phillip B.

> 24 hourTried this nozzle on the Creality Ender-5 with the Micro-Swiss All Metal Hotend. The hot-end printed the parts, but this nozzle caused tiny hairs to be pulled across the part when the hot-end moved. Adjusted all sorts of retraction settings, but couldnt get past the tiny hairs. This wasnt too big of an issue as I could hit it with a hot air gun that I use with heat shrink and clean them off. The real problem came in with bed adhesion. Using this nozzle, the PLA+ would not adhere to the bed through the entire print and caused warning. I replaced it back to the standard nozzle, using the same gcode, same temperatures, same material, same bed surface and my PLA+ had no issues with adhering to the bed. In the pictures, the part on the left is printed with the standard nozzle and the part on the right is the Micro Swiss MK8 Plated A2 Tool Steel Wear Resistant Nozzle. Same gcode used for both prints. You can see the adhesion problem with this nozzle and PLA+ Whatever they used to coat this nozzle for wear resistance, drastically affects the materials.

-

Richard Pomeroy

> 24 hourOnly negative is the hex is bigger than your average brass nozzles. Your favorite wrench wont fit.

-

Media.kraken

> 24 hourThese nozzles are the best, they last for a while