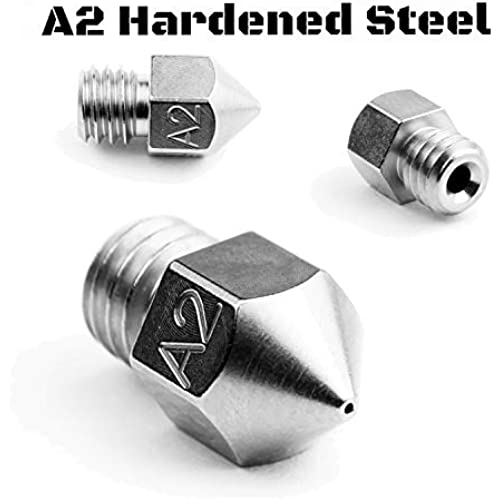

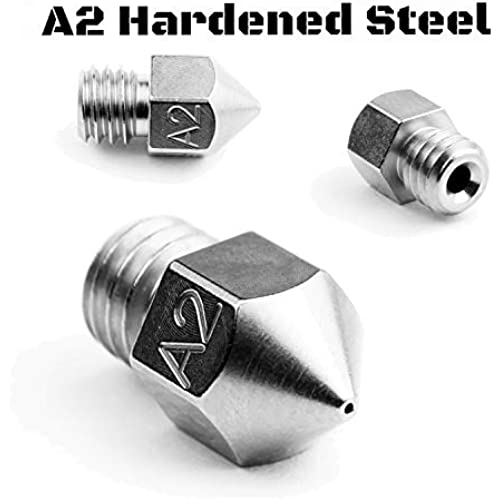

Micro Swiss MK8 Plated A2 Tool Steel Wear Resistant Nozzle (MakerBot, CraftBot, Creality, CR10, Ender 3, Ender 5, Tevo Tornado) .4mm

-

I make stuff

Greater than one weekPrints great

-

John

> 3 dayItem was received as advertised. I have not installed it as of yet but I am excited to so.

-

Jeff P

> 3 dayInstalled this on my CR-10S Pro with an upgraded Micro Swiss all metal hot end. Fits perfectly and is high quality. This allows me to print larger prints more quickly and spiralized (vase) mode with thicker walls.

-

Brandon

> 3 dayGreat little nozzle. Works awesome! They dont tell you to clean it though! Ours shipped completely blocked with black plastic or rubber.

-

Amanda Howell

Greater than one weekI almost exclusive print with carbon fiber polycarbonate and this nozzle has now ran through two full spools and hundreds of amazing prints the only thing I wish they would do is add a non stick coating to the outside.

-

Dylan

> 3 dayI see y every one seems to like them

-

Phillip B.

> 3 dayTried this nozzle on the Creality Ender-5 with the Micro-Swiss All Metal Hotend. The hot-end printed the parts, but this nozzle caused tiny hairs to be pulled across the part when the hot-end moved. Adjusted all sorts of retraction settings, but couldnt get past the tiny hairs. This wasnt too big of an issue as I could hit it with a hot air gun that I use with heat shrink and clean them off. The real problem came in with bed adhesion. Using this nozzle, the PLA+ would not adhere to the bed through the entire print and caused warning. I replaced it back to the standard nozzle, using the same gcode, same temperatures, same material, same bed surface and my PLA+ had no issues with adhering to the bed. In the pictures, the part on the left is printed with the standard nozzle and the part on the right is the Micro Swiss MK8 Plated A2 Tool Steel Wear Resistant Nozzle. Same gcode used for both prints. You can see the adhesion problem with this nozzle and PLA+ Whatever they used to coat this nozzle for wear resistance, drastically affects the materials.

-

Dave Hunt

> 3 dayIf you print anything thats abrasive like glow in the dark or wood then this is a must. I havent had an issue since switching from brass. Only change I made was I raised my print temp by about 5 degrees.

-

Richard Pomeroy

> 3 dayOnly negative is the hex is bigger than your average brass nozzles. Your favorite wrench wont fit.

-

Ramon

> 3 dayI needed a hardened nozzle for my CR-10 micro Swiss hot end, so I could print using Hatchbox Wood filament. Wood filament is supposedly abrasive, and I didn’t want the hassle of wearing out my brass nozzle, so I got this and it did the trick.