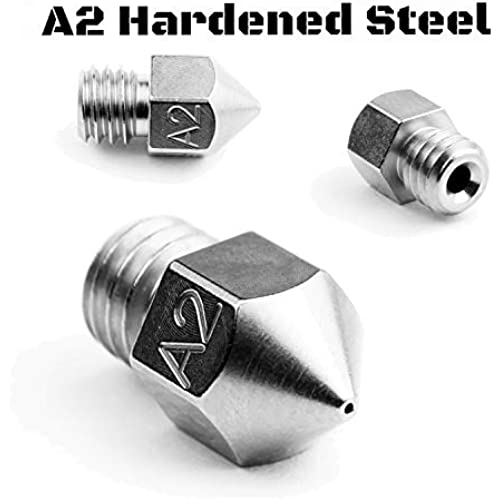

Micro Swiss MK8 Plated A2 Tool Steel Wear Resistant Nozzle (MakerBot, CraftBot, Creality, CR10, Ender 3, Ender 5, Tevo Tornado) .4mm

-

Peter

> 3 dayFor some reason Im really struggling to get decent prints out of it. I know that people say that for steel nozzles you need to increase temp, so I started by printing one of temp tower test prints. Of course I adjusted my z offsets and made sure everything is nice and tight. However, no matter the settings I cant get rid of stringing. PETG seems to really like to stick to the nozzle - which is opposite of what I read online. Putting standard brass nozzle fixes the issue instantly. For the price of this I can have like 20-50 brass nozzles that work just fine, so unless you go through a nozzle per week or less I dont see the point of buying this one.

-

Josh

> 3 dayI initially hated this thing. Couldnt get a good print. I thought I shouldve listened to the others. However, I have overcome. My printer and settings: Ender 3 Pro bed: 70 degrees Nozzle: 200-205 Printing with a glass bed. I ended up manually leveling my bed by letting a little bit of the filament run through the tip, and then having the nozzle just BARELY press the filament into the bed. Do that for all sides, let it heat up for an extra 5 minutes, and the nozzle worked perfectly. I make sure to set time aside with this nozzle, let it do its thing to heat up. Ive had nothing but perfect or near perfect first layers. PLEASE. PLEASE. PLEASE. make sure youre using your glass bed correctly (and not like me who forgot to remove the black material on the metal bed before installing the glass, I know, I am a wiser 3D printer today.) And PLEASE give it that extra 5-10 minutes to heat up after its reached the nozzle temperature. I went from what I thought was a waste of money to hoping these are still made in a year when I have to replace it.

-

Mitchell Kohlmetz

> 3 dayThe nozzle looks beautiful and performs with no problems. I got this nozzle to print abrasive materials in the long run and it is doing its job great.

-

PD

Greater than one weekI have been printing carbon PLA which chews up brass nozzles in no time. I have put several KG though this nozzle and its still as good as new.

-

Dennis P. Calderone II

> 3 daySeems like it will hold up longer than brass with abrasive materials. It does need extra heat. I will probably go back to brass and deal with the wear as it’s easier to dial in print temps

-

Caleb Campbell

> 3 dayThe all metal is great for those special filaments, I got it to work with wood and future exotic materials. The .6 allows for quicker print times with slightly less resolution which is fair. This nozzle can withstand higher temps too.

-

The Lord is my Shepherd

Greater than one weekI have a couple of spools of Luminescent Blue filament and a spool and a half of Carbon Fiber. Im told these filaments can wear out a brass nozzle in a single print so I needed something more durable. Tungsten nozzles were out of stock for a while, and the hardened steel nozzles were rated almost as tough, so I ordered and installed this on my Ender 3 Pro. I read online the process for swapping out a nozzle and gave it a go. No leaks, and prints come out fine.

-

Ramon

> 3 dayI needed a hardened nozzle for my CR-10 micro Swiss hot end, so I could print using Hatchbox Wood filament. Wood filament is supposedly abrasive, and I didn’t want the hassle of wearing out my brass nozzle, so I got this and it did the trick.

-

Amanda Howell

> 3 dayI almost exclusive print with carbon fiber polycarbonate and this nozzle has now ran through two full spools and hundreds of amazing prints the only thing I wish they would do is add a non stick coating to the outside.

-

Rodrigo Sosa

> 3 dayI received an used nozzle, it has filament remanents on it. Not sure how this can happen.