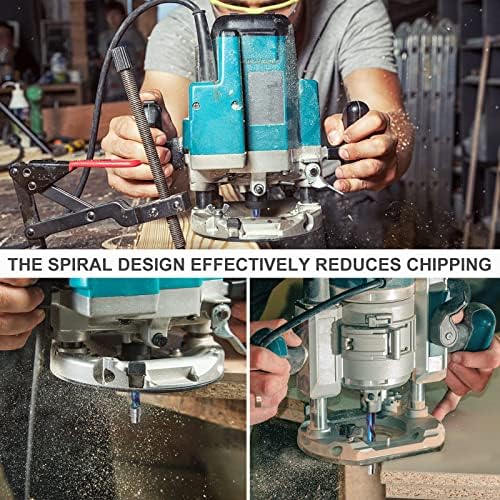

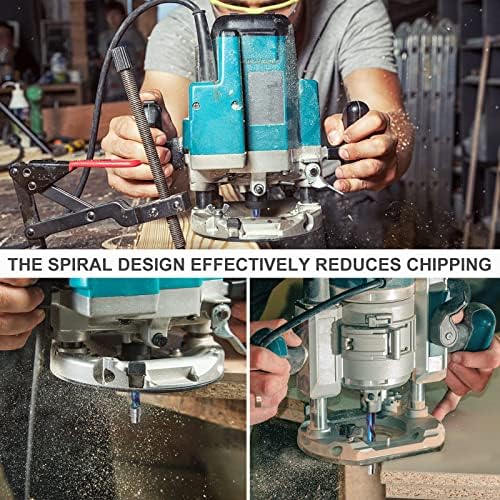

Up Down Compression Spiral Flush Trim Router Bit, 1/4 Inch Shank Solid Carbide Flush Trim Router Bits CNC Spiral Bit with Nano Coating by EANOSIC

-

Doyle Upton

> 24 hourAs it is an off brand from Amazon, I dont have high hopes for longevity. That being said, for a hobbyist the price is right and it works great so far. Only time will tell on durability.

-

RU!-Entertained

> 24 hourHmm, well this has a good cutting edge, seems to make a perfect edge, no wobble in the bit and good longevity. Good buy when compared to the same bit I got from HD at a better price.

-

Shaun King

> 24 hourThis bit is only used to produce repeatable results using a pattern attached to the workpiece as a guide. A bearing is used to follow the pattern and neither the process or this type of router bit are anything new. What sets this bit apart is that it cutting edges are slightly angled to slice both up and down. This results in a shearing cut rather than a chipping cut and should produce a smooth cut with little or no chip-out - well see. This is also a small diameter bit. Itll get into tighter areas, but its small size requires a bit more time and patience. You cant force this bit because its cutting tip speed is much slower than a bit of larger diameter. Both rotate at the same RPM, but the larger bit has to move faster around a larger circumstance. This little bit has the potential to produce edges ready for finish, but you cant rush it. Its also important to rough-cut work pieces very close to their finished size because you cant hog material with bits as small as this. This bit is for the last 1/8 give or take, youre not going to plow with it, at least not very far before it breaks from heat buildup. Use it as intended and with care and it shouldnt disappoint.

-

Bryan Noll

> 24 hourI took this little bit out for a spin and was very happy with the results. The pictures are with a piece of 1/2” plywood. I grabbed another piece to use below it to test out the bearing portion of the bit as well, but didn’t look to see that the edge was rough, hence the less than straight cut. This bit left a splinter free cut on both sides of the plywood. It cut quickly through the 1/8” of material I was trimming off. Just keep a few things in mind. This is only a 1/4” bit. Take it easy or you’ll probably snap it. The part of the bit that makes the clean upward cuts (just above the bearing) is small. As in about a 1/4”. You have to have the bit depth adjusted correctly so that the bottom of you board is inside that cutting area or else you’ll be using the downcut portion of the bit and probably get splintering.

-

Woodworx

> 24 hourBit works great, stays sharp

-

Blade

> 24 hourSharp and leave a good top and bottom finish. I have had no problems with bits from this company. easy to use.

-

Corey

> 24 hourThis bit is 1/4 from head to toe. So the bearing is also 1/4. Ive never seen one this small. Who knows how long it will last? Ill update if there are any problems. The blue coating and/or the flute design makes this bit cut very clean! For the few materials I tried, there were no blowouts or chads left hanging on top or bottom! I didnt have any kind of chatter or wobbling that I expected. However with the tiny bearing diameter, it will definitely transfer smaller imperfections from your template to the workpiece. More so than with a 1/2 bearing. This is just a lot easier to work with. I think youll have to be careful not to rely on bit color to tell you when youre making too much heat. You wont see discoloration on this coating. I guess youd have already made way too much heat if your bit was bluing. Best to keep your pass speed under control anyway.

-

AminA

> 24 hourI am giving this particular bit 3 stars, because it could have been a rare manufacturing flaw. I used it on a 1 inch cherry wood removing about 1 to 2 mm, and after about 5 minutes and 2 feet it fell apart. Luckily I had an upcut bit by the same manufacturer that I used to finish the work. The other bit performed perfectly.

-

Keith

> 24 hourThis is my second bit from Eanosic and just like my first one I am happy with it. It comes in a nice case for protection, and it is very sharp. It cuts material cleanly and the up down compression leaves nice edges on both the top and bottom as long as you set the bit up correctly. It is not meant to take much material off so you will need to use a bandsaw or jigsaw to cut away most of the material first. I only use it for pattern routing which is what it is meant for. Pay attention to the size of the material you are using because you may need to get a larger bit. I am using it for 3/4 material and it works great. Very happy with this bit.

-

Bruce Regittko

> 24 hourI have a 1/2 up cut flush trim bit but need something smaller for a tight inside corner. I expected this bit to produce about the same quality cut as my bigger, premium bit. This bit cuts better! The up/down compression really eliminates tear out on both the top and the bottom of the work piece. While I have not used this bit enough to rate its durability, I will be grabbing this before my other bit next time I need to flush trim a piece.