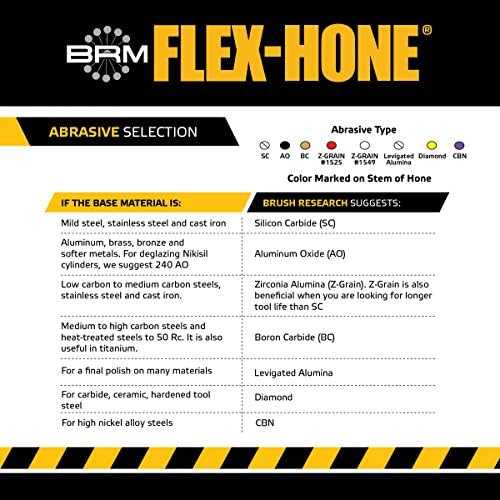

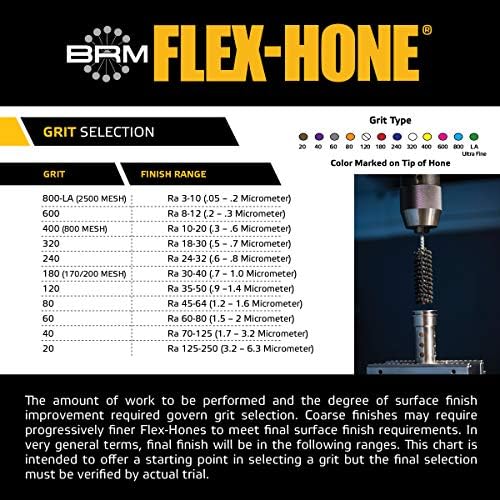

Brush Research FLEX-HONE Cylinder Hone, GB Series, Silicon Carbide Abrasive, 4-1/8 (105 mm) Diameter, 240 Grit Size

-

david

> 3 daygood price worth it

-

BT8850

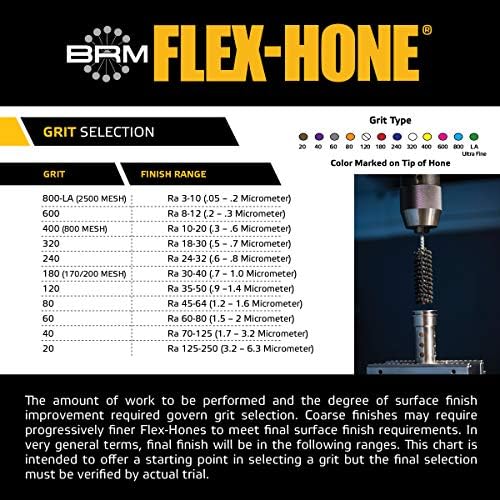

Greater than one weekExcellent product. Brush hones are a very good thing to have around and BRM makes about the best ones. The price on amazon is inline with just about everywhere else so cant complain there. I used this particular hone on a standard bore small block ford engine block to hone the cylinders before I installed the pistons and rings. The 180 grit has worked great for me with standard Iron piston rings. If youre using moly rings or something else, refer to the manufacturers recommendation when choosing grit size. I also like the brush hones because you can purchase one for less than a machine shop will charge you to hone your cylinders, and you can usually do more than one block with one. The last BRM hone I had did 5 small blocks and still has some life in it. Take that for what you will. Very good product at a very good price. Definitely recommend for your rebuild or re-ring project!

-

jeff beary

> 3 dayBought this to rehone the 3.8 Buick cylinders after trying to use them old stone three arm hone devices. I have no idea why I ever thought that contraption would ever work. This thing is a beast. Takes seconds to use properly and I didnt have a second thought about putting the crank back in and hooking up the Pistons. If you ever plan during your mid-life crisis that you must rebuild an engine, save yourself some time and get this and the next grit under and use these to perfectly hone your sbc or whatever man.

-

Tom Estep

Greater than one weekGood Tool

-

joe paquette

08-06-2025Item worked as advertised. Provided quality hone in my cylinders.

-

Carjones

Greater than one weekCouldnt find in stores, these are great for mild rebuilds. Cleaned up cylinders in just a few passes. Use care cleaning up as grit and tool material gets everywhere.

-

DIY or Die

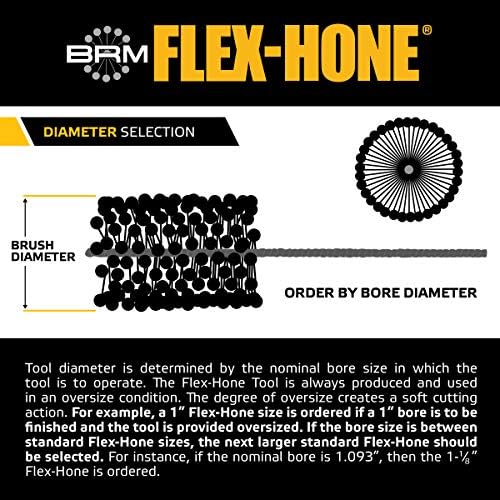

08-06-2025Buy exact fit to the .10 or one .10 larger Working on a 22r Toyota stock bore 3.6. This hone did its job with a nice cross hatch. However, the hone just barely hit the bore walls. Maybe this is by design but I feel I should have gotten the 3.75 bore hone as my bore size is 3.6 If your bore is 3.5 then you would be fine. The hone would have a bit of pressure on the bore walls. If you plan on honing a 22r look for the next size up. The balls on the hone wore down Farley fast making flat spots on most the balls. So when you use this you do not want to hone one bore at a time. Make like 2 passes per bore to break in the hone tell you have broke the glazing off the bore walls and broke in the hone, then work on your cross hatch pattern. Over all I like this hone and its ease of use but the fact that I most likely will not be able to use it again, I may get one more use from it in 5-8 years witch would pay for it self then but a stone hone would be more cost effective. If you build the same 3.5 size bore engine all the time this hone would be ideal. Cause you can just grab put in drill and hone (adding cutting oil).

-

John

> 3 dayThere is nothing to dislike about this hone. It does exactly what it is suppose to do. Been using these hones on motorcycle cylinders for years and they work great everytime.

-

Brian

Greater than one weekI have a 3000 mile freshly rebuild 355 sbc. Went with new rings rods and pistons.. A quick Hone to knock the glaze off was exactly what it needed. Does a great job !!

-

Rory Boehm

> 3 dayRecieved way sooner than expected. Very happy. Thank you!