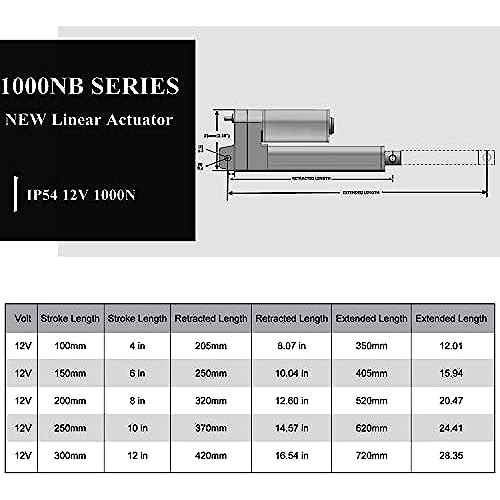

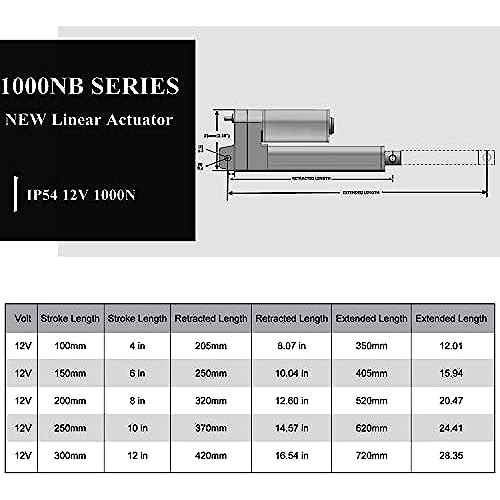

DC HOUSE 12 Inch 12 High Speed 14mm/s Linear Actuator Motor 1000N DC12V with Mounting Brackets

(0 Reviews)

Price

$39.99

Share

92 Ratings

Reviews

-

Jim & Tella Freiling

> 3 dayNot exactly what i would call High Speed, but they work and theyre powerful.

-

LonnieK

02-06-2025An actuator on my 2009 F-150 Lariat bed cover broke. No replacement could be found. Needed 200mm lift and a faster speed (from 10mm to 14mm/sec.). Slight modification required to fit the lift hardware mechanics. Everything works great. Very happy with product.

Related products

Shop

(

430

Reviews

)

Top Selling Products