Yamation DTF Powder Adhesive White 500g / 1.1lb DTF Transfer Powder Hot Melt Adhesive applies to All DTF Transfer Printers for Digital Prints on T-Shirts Textile DTF Supply with DTF PET Film and Ink

-

Hyp

> 3 daySmooth and fine DTF transfer powder. Works well with my DTF print. Fast delivery. Will buy again!

-

Nekesha P.

> 3 dayIts ok...would of been better if the powder was much finer.

-

Tsahai Arnett

> 3 dayI used this and can now see the difference in my products the colors pop more

-

Christine M

> 3 dayPackaged and shipped with care. It works as expected so am now able to sublimate on cotton fabrics. Highly recommend.

-

Elisa F.

Greater than one weekEl diseño no se adhiere en la camisa, cuando remuevo el papel se quedan pedazos sin diseño

-

EdisonDairo

10-06-2025Its the first powder adhesive I use for DTF, but I get perfect prints every time, even on small text elements. will buy again.

-

TASWIYAH CASSEUS

Greater than one weekDid what it was suppose to.

-

Daughter of time

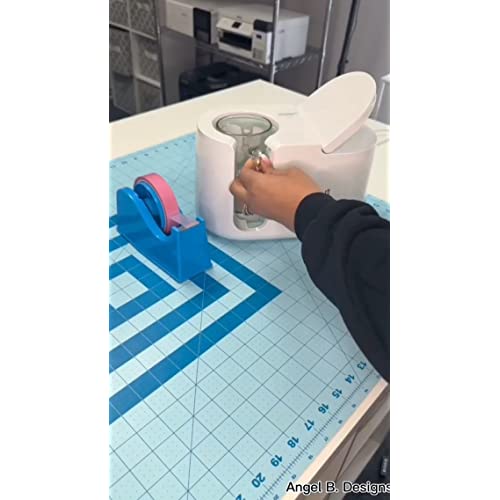

> 3 dayIve been doing sublimation for a bit now, but when I saw the dtf hack I had to try it. After watching a million videos on how to do it, I chose yamation because this was easily the most recommended powder. So far it works amazing. It melts well and so far has adhered well to any fabric.

-

samantha

> 3 dayNot sure what im doing wrong but it didn’t work for me and while pressing there were smoke and smell that would make my eyes watery

-

dar

Greater than one weekProduct is fantastic! So happy that I can use this on cotton!