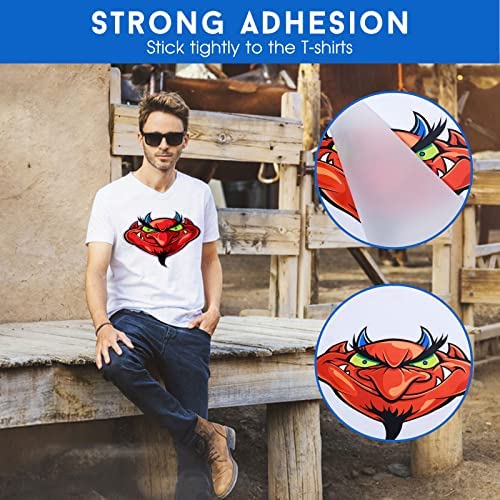

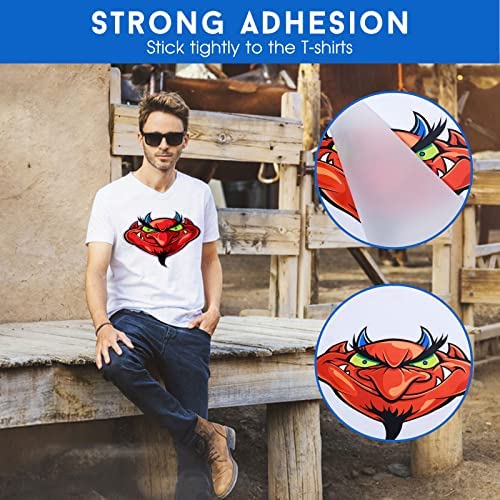

Yamation DTF Powder Adhesive White 500g / 1.1lb DTF Transfer Powder Hot Melt Adhesive applies to All DTF Transfer Printers for Digital Prints on T-Shirts Textile DTF Supply with DTF PET Film and Ink

-

Peter Weyland

> 3 dayI had some reservations about using this at first. Because I obviously didnt want to have botched jobs. But I read really good things about using this particular type of powder. And sure enough the results were much better prints. So you get an end result that you feel better about whether youre gifting the shirts, or using them to sell online.

-

Cynthia Lewis

> 3 dayIf the bag was resealable it would have been the best

-

Eve

> 3 dayI used this with my sublimation print on dtf film and it worked really well. It heated really easily and transfered to my shirt perfectly. This brand is really good every time I use it.

-

EdisonDairo

> 3 dayIts the first powder adhesive I use for DTF, but I get perfect prints every time, even on small text elements. will buy again.

-

reallyrob

> 3 dayThis Yamation DTF Powder works really good! I have been trying many brands to find which one works best for me and my needs. I must say, I am not using this as it is supposed to be used...I am doing a sublimation hack and using with sublimation inks. I can say that this powder worked good for me. The colors were vibrant and still looked good after one wash so far. I will keep this review updated after some more washes, so you can know how well the shirts designs will hold up using this powder.

-

Crafts and More with Christina!

> 3 dayQuality of image looks great, transfer was nice and smooth. Do recommend.

-

Charisse

> 3 dayYamation DTF Powder Adhesive White 35.2OZ/ 2.2lb DTF Transfer Powder Hot Melt Adhesive works as designed. It coats well without clumping and the excess is easy to tap off. Works better with polyblends or polyester better than 100% cotton.

-

Alicia Villalpando

Greater than one weekFirst time using this product, and overall it was pretty good. My first few shirts came out really nice. Powder took well to film and pressed well. Then I had a few shirts that it didnt still all that great. Had some light areas that didnt adhere as well. Sometimes it happens with some DTF powders. Im going to keep using the product and see if this issue continues. Not bad though.

-

Saliandra

> 3 dayIt has been a frustrating experience to do the sublimation DTF hack with Yamation film and powder - I went through about 25 sheets of film trying to get it to work (argh!). For anyone else frustrated with streaks/roller marks on their film, I found that I could change the print density by going to the Maintenance Tab (of my Epson SC-F100) and selecting Extended Settings. From there, I dragged the slider to the left so it was around -25%. This eliminated most streaking for me. If a design has a lot of black in it, maybe go even more negative with your number. If a design doesnt have much black at all, then go for a smaller negative number. I can get away with about -5% for an image with little to no black. Other things that might work for you are to choose the Rigid profile, or to choose Standard quality. But I use the Textile profile and high quality and then reduce the print density as described. I bake my powdered design at 385 degrees for 2 to 3 minutes on the bed of my HTVRont auto press. Obviously, I dont bring the press down, but just let it hover. Because it is a few inches above, it takes more than a minute. Because the sublimation ink has already been activated through this process, it isnt necessary to press the design at such a high temperature as you would with sublimation. After having conquered the problems with streaks, I then went about experimenting with pressing times, temps, and pressures. Following the recommendations on the package for temps and times did produce a nice result on the shirt, but the designs were degrading quickly upon washing. After a bunch of further experimentation, I found that I needed to do a higher temp and higher press time in order to have the design really adhere and last through washings. I think the success of this whole process really depends upon your equipment - basically your press and your printer and your ink. Be prepared for problems in figuring it out. Now that I HAVE figured it out for my setup, I do like the products and will continue to use them. But boy oh boy, was this a struggle to get it right! Note that for the Epson SC-F100, I do NOT need to apply the film to a piece of paper with tape, as others would tell you. It feeds right through my machine with no issues as is. If you have a different printer, your experience may be different. For anyone who has the HTVRont auto press trying to do this hack, put a pressing pillow beneath your garment to trick the press into applying more pressure. Also, for me, I need to press at 345 degrees for 45 seconds to get a good result and to get the design to last through washings. I do NOT do a second press with a teflon sheet on top as others recommend. This tends to remove ink and degrade the design in my experience. I find that after the first washing, the design feels more embedded into the fibers as it would if you did a second press anyway.

-

m ann mccammon

> 3 dayThe only reason I’m giving it a 1 is because I received the package damaged. When I opened it the powder was in the box and there were tiny slashes/holes around but not enough to make the product go everywhere in the box.