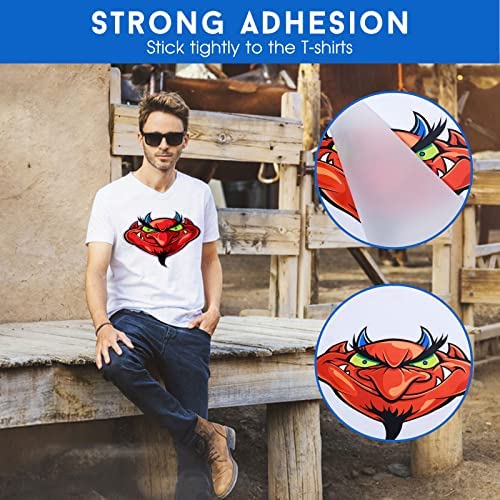

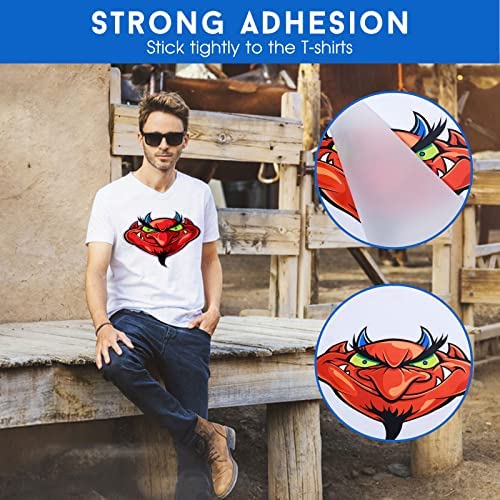

Yamation DTF Powder Adhesive White 500g / 1.1lb DTF Transfer Powder Hot Melt Adhesive applies to All DTF Transfer Printers for Digital Prints on T-Shirts Textile DTF Supply with DTF PET Film and Ink

-

LISA RACZ

> 3 dayI found that too much powder attached to the ink. Shook it tapped it on the table and from behind still seemed to be too much. Also difficult to melt it down or cure on a clam press. Not sure how I really feel about it yet it’s only my second one. Definitely need pedi to press hotter and longer on the shirt then the recommended times and temps

-

Cynthia Lewis

Greater than one weekIf the bag was resealable it would have been the best

-

Ottilie Koss

> 3 dayEverything came out special!!

-

Michelle

> 3 dayI have never used dtf powder before in my life, but for my first try, it worked great. I used my inkjet printer to print on the film. I then coated the film with the yamation fine powder. Heated it up with a heat gun until it melted. Coated it once again and pressed it onto my medium. It came out great! Adherrd perfectly. It did dull out a bit, but thats probably just because I used an inkjet. I am not mad at the results at all. It worked out great. I will be trying different dtf powder so I will come back to compare it to others.

-

Christine M

> 3 dayPackaged and shipped with care. It works as expected so am now able to sublimate on cotton fabrics. Highly recommend.

-

Rosa

> 3 dayI had high hopes but No it faded after first wash.

-

Charisse

Greater than one weekYamation DTF Powder Adhesive White 35.2OZ/ 2.2lb DTF Transfer Powder Hot Melt Adhesive works as designed. It coats well without clumping and the excess is easy to tap off. Works better with polyblends or polyester better than 100% cotton.

-

Cee

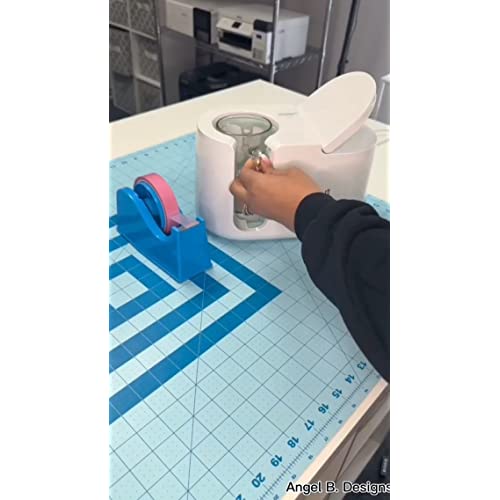

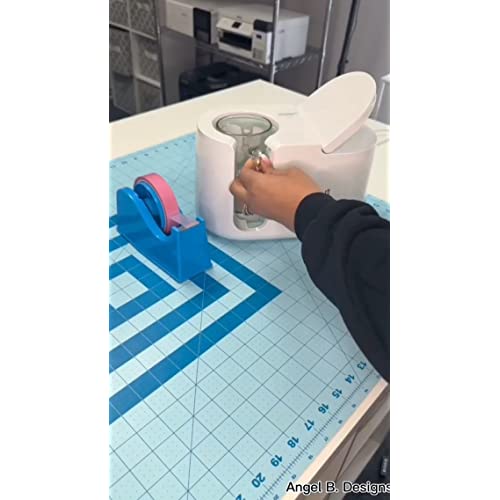

> 3 dayI thought this product would be in a canister as pictured but it comes in a bag. The powder works great, I used it with sublimation ink and cured it with a heat gun before applying to my shirt.

-

Daughter of time

> 3 dayIve been doing sublimation for a bit now, but when I saw the dtf hack I had to try it. After watching a million videos on how to do it, I chose yamation because this was easily the most recommended powder. So far it works amazing. It melts well and so far has adhered well to any fabric.

-

Crafts and More with Christina!

> 3 dayQuality of image looks great, transfer was nice and smooth. Do recommend.