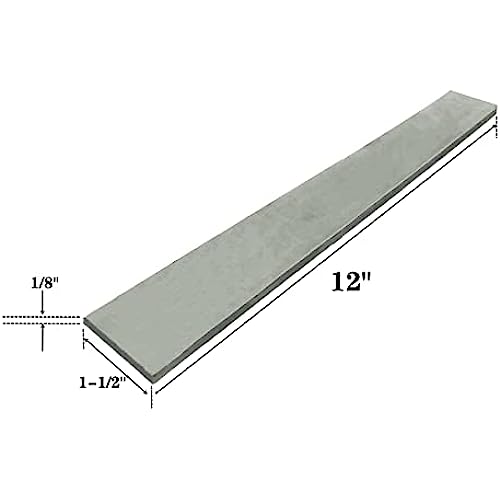

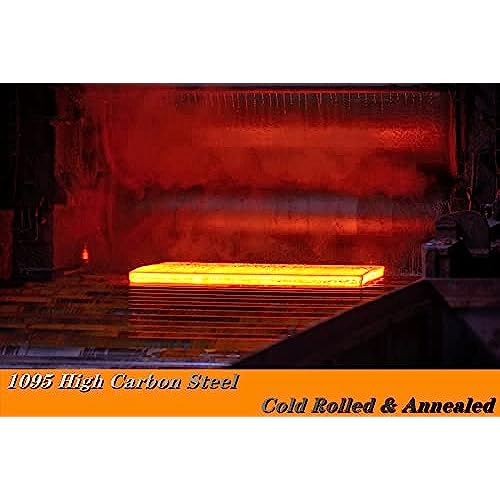

1095 Steel Flat Stock for Knife Making-Annealed High Carbon Steel,Flat Steel Bars,12x1.5x0.12,4 Pack

-

Nilo s

> 3 dayIts a very nice 1095 flat bar, ready to use. Was shipped fast! Good quality steel!

-

Cuban Comanche

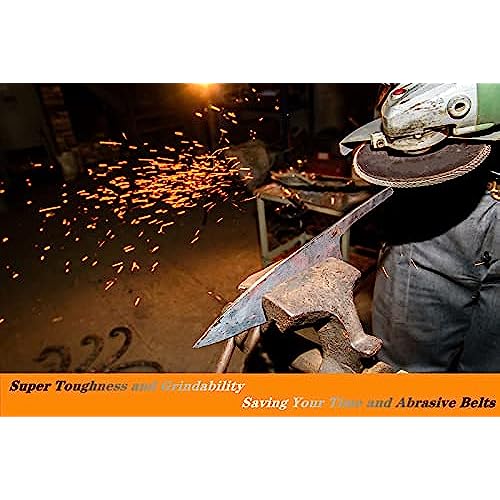

> 3 dayI used this 1095 to make my own version of the Condor Bushlore. Pretty identical only 2 longer and with a nice set of tigerwood scales. The steel came annealed for easy machining and after two thermocycles I got the steel to bright orange (non magnetic) and plunged it into some Parks 50 quench oil. Tempered for 1 hour at 400 degrees. I am really pleased with the toughness, hardness and razor sharp efficiency of this blade. . .ordering again today!

-

RAC13

07-06-2025These blanks came well protected with a shiny coating of oil to prevent rust. We will be making a knife from them as soon as time permits and will report back with pictures of the final product. So far they look like they will be perfect for the job.

-

CaroleO

04-06-2025I am not a knife-maker -- yet! But these steel bars are exactly what I wanted. They appear to be just as they are advertised, and Im happy with them.

-

Kevin Burgess

Greater than one weekMy son has his own forge and makes knives, so he was super happy to receive this from me. The size of them is perfect for his needs and he said they worked great in the forge.

-

Kristen Rockwell

> 3 dayIts shiny, its hard, its magnetic, seems to be exactly what I ordered. Im no expert in making sure its exactly the type/hardness its supposed to be, but either way its steel, and the dimensions are correct. Came packaged well, no moisture, no rust. Ill be sure to update this review after working with some of the pieces, but Im sure Ill be just as pleased with it then as I am now. If you need some small pieces of flat stock for making things, this will do just fine.

-

Michael Brown

Greater than one weekSpark tested this, definitely high carbon. The packaging, as others have said, was good. No rust, no pitting, very light oil, fast shipping, and everything got to me undamaged and not bent or twisted. Looking forward to testing really testing this steel.

-

Dinara

> 3 daythats what im calling cheap but best. after finishing cutting edge is razor sharp, but really needs oiling after using, because even after one single day its surface getting rust

-

Sarah

> 3 dayHigh carbon steel worked great for stock removal knife making

-

Eric Esquilin

> 3 daywell the steel was blemish free, flat straight and rust free.. nice if your getting into blacksmithing! I would have no worries about ordering this item ! can I prove the material is what it claims to be ...no can I make a blade out of it and find joy in the journey.. Yes !