Brush Research FLEX-HONE Cylinder Hone, GB Series, Silicon Carbide Abrasive, 4-1/8 (105 mm) Diameter, 240 Grit Size

-

vbr

> 24 hourworked perfect to deglazed cylinder wall on 2003 Ford Focus 2.0L SPI , also known as the dropped valve seat engine SOHC. Adds a nice crosshatch to cylinder. Directions for use were on end of brush box.

-

Sky Gentry

> 24 hourThis is the only hone to use on engine cylinders. I am a master mechanic and the reasons are many. The cross hatch pattern this hone makes is the best for breaking the glaze on new rings and seating them in. Brake type hones are good for rubber seals, plungers, etc to steel bores but not for high friction steel to steel applications. Dont be a cheap skate when it comes to your engine - Go with the best parts and practices. Also, dont use Synthetic oil in engines with new rings. Get at least 500 miles on them and then switch to a synthetic (Same Brand) if you want to use it.

-

John O.

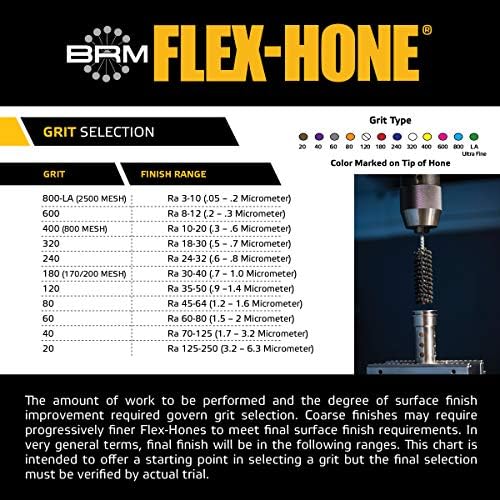

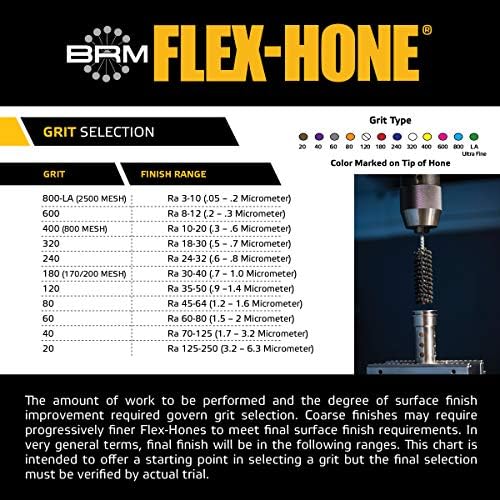

> 24 hourThese guys make the best hones I have used over 30 years. If you use this hone correctly you can bore a cylinder out 10,000ths top to bottom evenly for 10 over pistons and rings. I do this in a variable speed drill but it can be done in a drill press too. You must check all points in the cylinder often, cleaning as you go. Use a coarse hone to get most of it then change to a hone grit specified by your piston and ring manufacturers. Clean the cylinder and oil it testing with the piston for clearance. Use your micrometer til you reach spec so you dont get your piston stuck in the cylinder. Dont Rush!! Watch a cylinder honing machine on you-tube to understand the motion you must use to keep the honing even. Always use a quality honing oil.

-

Howard Brown

> 24 hourGot the hone oil a must to keep it wet. My option.

-

Alan

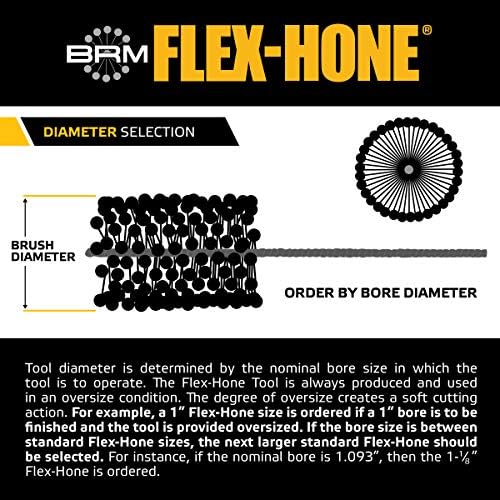

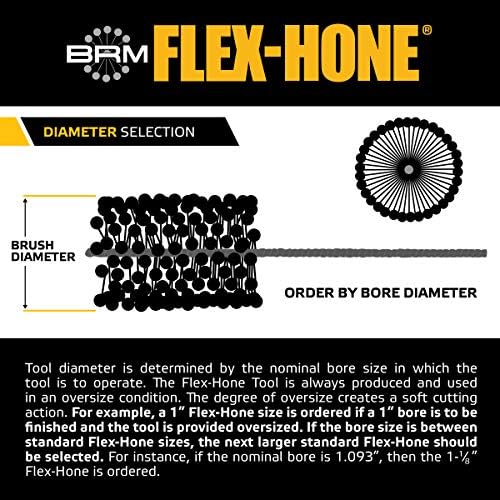

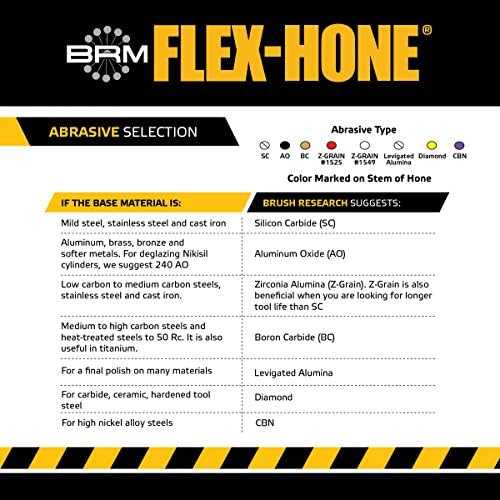

> 24 hourThis seems to be a well made tool. The abrasive tip is connected to the metal center with plastic leaders but they seem to be sturdy enough to handle the work. If you are reading this you know what it is for and it seems to fit the bill quite well. Keep in mind when purchasing that you will want to make sure you get the size and grit needed for your application.

-

Panhandle Fred

> 24 hourdoes a super job leaving a cross hatch pattern in the cylinder.

-

Joshua N.

> 24 hourGood product and it got the job done on a golf cart engine that I was rebuilding but I did have some of the turds come off of it at the end of the hone. Worked very effectivly and once the few turds came off right away didnt have another issue with it. No more than I will be using it I couldnt justify buying an expensive one but I am still very pleased with this product cause it still got the job I bought it for done

-

Eric S Woodring

> 24 hourIf your looking at buying it, then you know what it does. I hope your engine livesca long, happy life.

-

Akruck

> 24 hourJust used it on one aircraft cylinder, but it did an amazing job. Other mechanics in the shop were equally amazed. The cylinder broke in very well.

-

S. Ziemba

> 24 hourI bought this for my 1997 SeaDoo Speedster engine repair. I originally honed it with this but then found out I needed to get the cylinder bored over for other reasons. I took it into the machine shop and the machinist was in awe how amazing the cylinder looked he was wondering why I was even there. The cross hatch this tool leaves is second to none. This is a must have for anyone who regularly works on engines, but keep in mind these are fitted for specific size bores. If you just need one for a different size bore every time on new engines you work on, it might not be cost effective for you. For me, I would rather accumulate a whole set...so its all good for me.