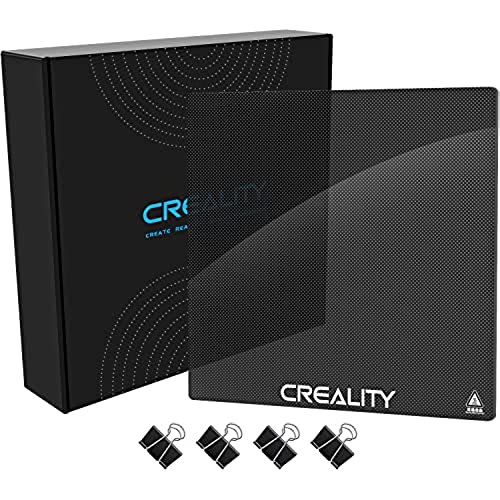

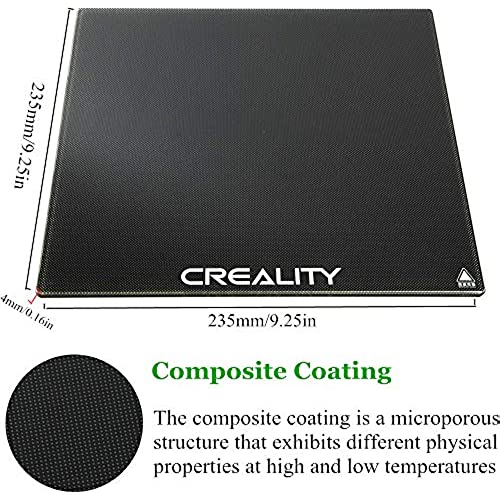

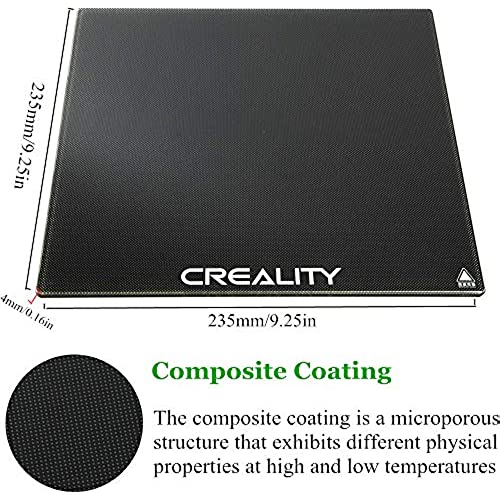

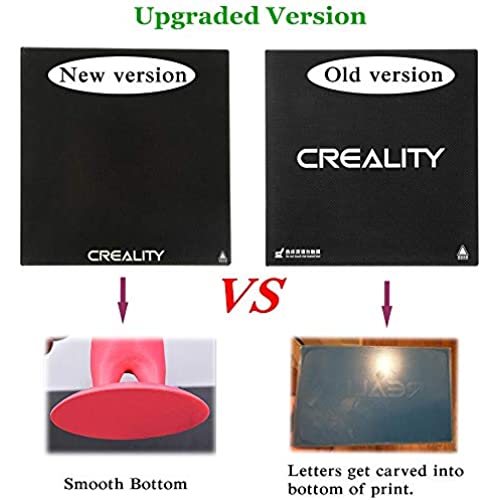

Creality Ender 3 Glass Bed Upgraded Platform 235x235x4mm for Ender 3 S1/ Ender 3 / Ender 3 Pro/Ender 3 V2/ Ender 5/ Ender 5 Pro, 3D Printer Tempered Glass Build Plate Surface

-

Tom Brown

> 3 dayParts stick well. I liked it so much I bought one as a gift.

-

Erik G.

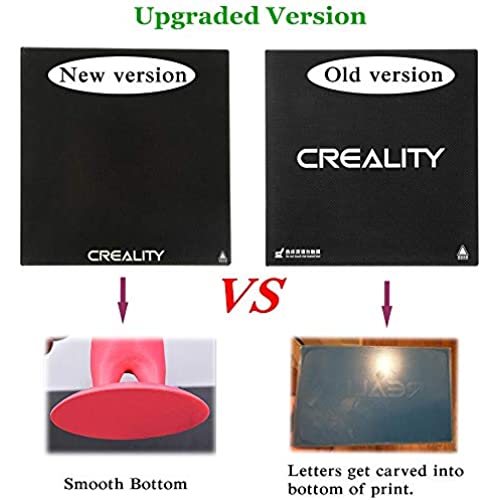

> 3 dayBeen using for a bit and havent had any issues yet. Printed dozens of items and all stick and release super easy. There are a couple of different textured glass beds similar to this, and they all work the same way. When the glass bed is heated and printing, the plastic sticks to the texture on the glass since it has little divots. Much easier than just plain glass that is too smooth and wont adhere correctly unless it is perfectly leveled and cleaned. Then once the glass cools, the textured material actually contracts, popping off the print. No need to pry anything off, just a little push or pull and it pops right off. Tip: dont use any glue or anything like that. Just keep it clean and it will work as intended. Also, many people like to use binder clips to hold bed surfaces down, but they get in the way and annoy me. Just use some masking tape along some of the edges and it will stick fine, as shown in my picture.

-

Stampede Fan

> 3 dayUnless you plan on using adhesive this bed is terrible. You would be better off buying a piece of glass and putting a creality bed surface sticker on it. Thats how I made this bed usable.

-

Moldy Taco

> 3 dayI will never go back to using the printing mat, printing on glass is so much better.

-

Josh

> 3 dayI really wanted this to work. I even bought a thickness gauge to ensure proper height of the nozzle and everything was perfectly level. The failure lies with poor adhesion. I now need to see if print bed glue will help.

-

David Hovemeyer

> 3 dayI bought this to use on my Ender 3 because the original (fiberglass?) build plate was significantly warped. My first print on this glass build plate didnt adhere, so I cleaned it thoroughly with isopropyl alcohol and also raised the bed temperature from 50 °C to 55 °C. That did the trick, and Ive done multiple prints that have turned out perfectly. So far its been very easy to remove the parts from the plate (much easier than the original plate): basically, they snap right off when the print is done. I only print using PLA, so I cant vouch for how it would work with other materials. One issue to note is that you will need larger binder clips, since this plate is much thicker than the stock one.

-

Ryan OConnell

> 3 dayThis bed is awesome, I started a print before bed and when I woke up in the morning it popped right off. it also fixed the slight dip that was in the middle of my stock ender bed. heats up well and got here super fast!

-

jose r garcia

> 3 dayGood adhesion if you keep it clean and slow down the initial layer print speed to around 10mm/s. No need for glue. My ender 3 bed is warped, and this bed helps solve that problem by providing a very flat surface that is very even all around. Just make sure to raise the z endstop because this is significantly thicker than the stock plate. Prints come right off when the plate cools!

-

Mike C

Greater than one weekNothing to complain about for the tempered glass. Very smooth finish, and easy to clean. Just remember the basics of a tempered glass build plate; it takes 2x as long (or more) to heat up, you should wait for it to cool completely before removal (due to the porous nature of the material) and dont forget to adjust/recalibrate your Z-height after installing (it is quite a bit thicker than the removable magnetic build surface). Worked great on my Ender3 Pro.

-

McFlurry

> 3 dayThe original magnetic base was easily damaged at ABS print temps. The glass replacement has no problems.