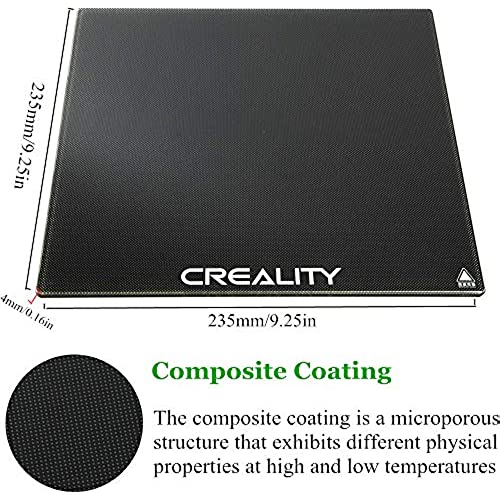

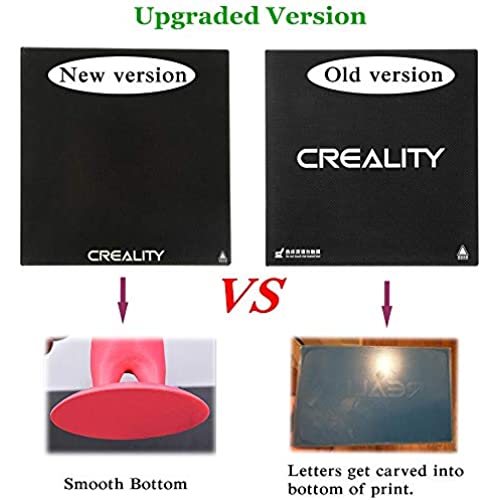

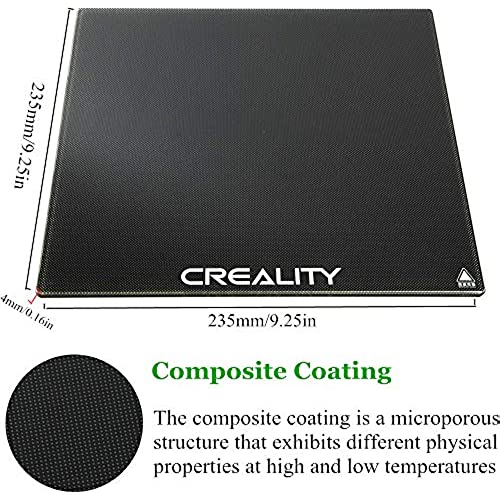

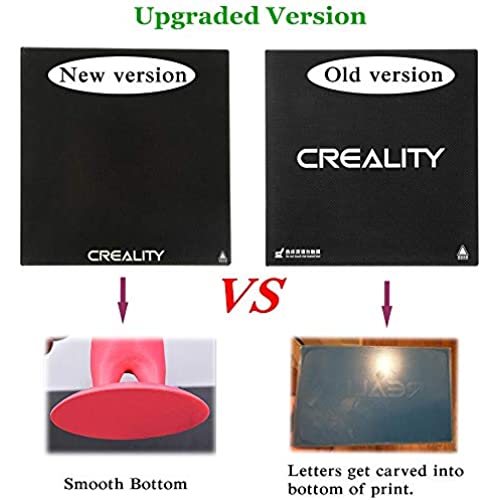

Creality Ender 3 Glass Bed Upgraded Platform 235x235x4mm for Ender 3 S1/ Ender 3 / Ender 3 Pro/Ender 3 V2/ Ender 5/ Ender 5 Pro, 3D Printer Tempered Glass Build Plate Surface

-

Justin Vanhaverbeck

> 3 daySeveral days of testing at every appropriate temperature, nozzle height, initial layer speed, using a thin layer of hairspray, then a thick layer of hairspray, then a glue stick, and then re-cleaning the bed with dish soap, alcohol, and not touching it at all, I have decided this bed will NEVER have any adhesion with my prints. The stock Ender 3 bed was effortless adhesion with any filament once calibrated. Completely useless. It was also not completely flat in the center.

-

Dstone

> 3 dayJust a word of caution for folks with a magnetic Creality hotbed. Do not place this glass plate directly onto of the magnetic hotbed. It will fuse itself to it if you print with higher hotbed temps (75+). If you plan to use it on a printer that has a magnetic hotbed, such as an Ender 3 S1 Pro, place it on top of the magnetic PEI bed. The plate itself works great, but it is now a permanent part of my hotbed.

-

Phil-Bill

> 3 dayI’ve been getting PERFECT first layers using this print bed. HIGHLY recommend! And I recommend using 65 degree Celsius for printing, DO NOT remove your print from the bed until it cools down to 35 degrees.

-

Lena

Greater than one weekYay no more dip in the middle of the bed! You will need to supply your own clips but that’s easy enough. My frustration level just went down!

-

Eduardo

Greater than one weekI bought this, and unfortunately the pla doesn’t stick well to the bed, it is easy to remove when hot and it shouldn’t. If I am doing something wrong please enlighten me, I have the bed at 75 sometimes 85 because it won’t stick at the regular 50 to 60 temperature, I do have auto bed leveling, I thought this product would work great but it hasn’t for me

-

Nick

> 3 dayJust buy it... they are night and day better than flex plates... coated to allow strong adhesion with heat and as it cools the print becomes easier to remove... don’t try to remove when you are at temperature... Most likely you won’t be able to… I am not paid by anybody I am brand new to the printing world and I will be buying this product over and over…appreciate the coating and the less hassle with leveling...

-

James Arjuna Sr

> 3 dayI make parts and so I need to use stronger materials for function in machines. PETG, PETG Carbon fiber, And PC carbon fiber. The temperature for the bed is higher and normal removable flexible build plates dont work. Even the ones that come with the PETG get stuck and are destroyed after one print. This holds up about 9 months of continuous use. And I use a build plate adhesive designed to allow the PETG to be removed without sticking to the glass. I may try some smoot glass, but the bottom surface is fine with this, textured surface.

-

Daniel Rosicka

> 3 dayWorks and fits great on my Ender 5 Pro! No need for anything to hold it in place no clips no nothing it just stays in place. Also all of my prints stick to this bed fabolously without any glue or anything, would definatly recomend this product.

-

JOSEF

> 3 dayThis is probably the best upgrade Ive made for my ender 3 besides springs. It made my printing and bed leveling soooooo much better. The magnetic bed is OK but since some enders are prone to have a dip in the heating bed. My leveling was always a little off. But since putting on this bed. It has been working amazing. I Dont have adhesion issues anymore either. Ive been printing TPU without that many hitches at all. Once my slicer settings were dialed in. They print great best purchase Ive made for my ender 3 so far.

-

REN

> 3 dayBeautiful piece of glass. But I prefer function over form. I leveled this correctly, with the proper nozzle clearance and started printing. PLA would not bond. Tried hair spray, edges curled. Tried a brim, brim would not stick. Tried a raft, not much better. Very disappointed. Maybe it works great with ABS. I went back to the smooth glass plate. UPDATE: Stupid is as stupid does. I was using ABS by mistake with PLA parameters. Working better now!!!!