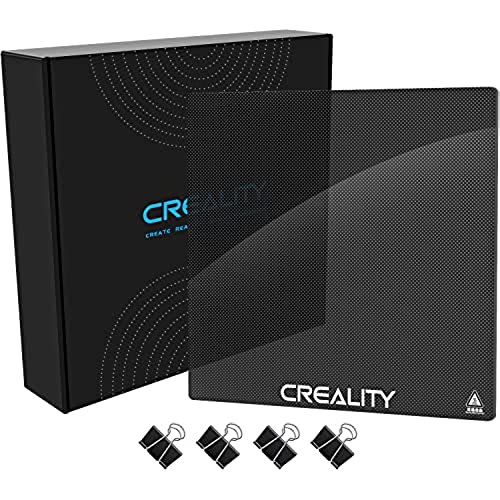

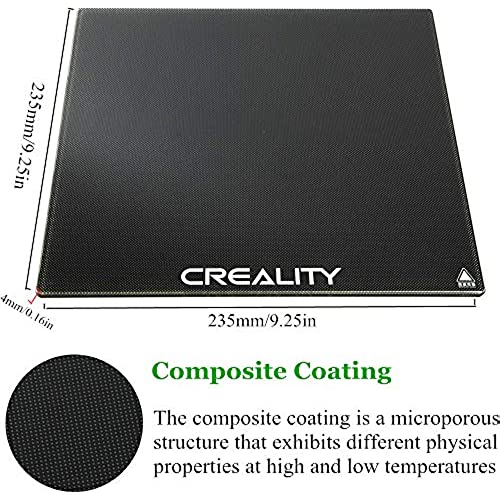

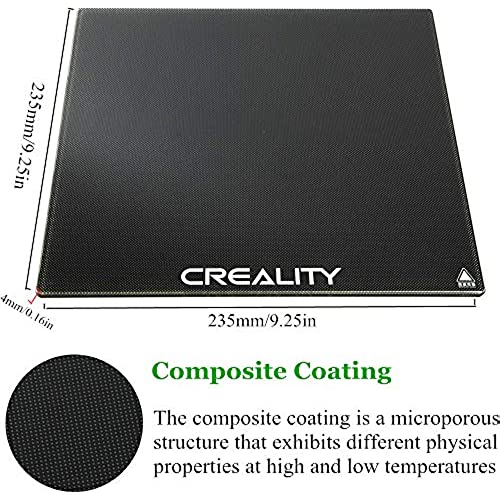

Creality Ender 3 Glass Bed Upgraded Platform 235x235x4mm for Ender 3 S1/ Ender 3 / Ender 3 Pro/Ender 3 V2/ Ender 5/ Ender 5 Pro, 3D Printer Tempered Glass Build Plate Surface

-

Thompson

> 3 dayVery easy to use! Do wish it came with bed clips. Occasionally I will need to use a glue stick to help keep corners down, but I believe it might be due to having the bed not hot enough (it’s usually around 60 degrees and I should set it to 65 degrees). Overall I would definitely recommend this glass bed!

-

Tango_542

> 3 dayIts nice arrived super fast, got it out put it on my printer and went back to look for the locking clips...nothing... tried original clips for basic print mat... WAY too small... so now I get to wait a few more days and order some clips, thanks for the heads up...

-

Matthew p.

> 3 dayThe filament won’t stick to the bed no matter what settings I use, what temp I use. Nice bed otherwise but If it cannot keep the filament in one spot, it doesn’t work.

-

Stampede Fan

> 3 dayUnless you plan on using adhesive this bed is terrible. You would be better off buying a piece of glass and putting a creality bed surface sticker on it. Thats how I made this bed usable.

-

Draw H.

Greater than one weekIt is not sticky at all -- I tried level the bed for 10ish time and tried multiple bed temperature. It doesnt come with even super cheap metal clips, so you have to buy them yourself. When you put metal clips on, the glass bed is not flat anymore --- actually the glass bed itself is not flat anymore once you put it on.

-

CALEB

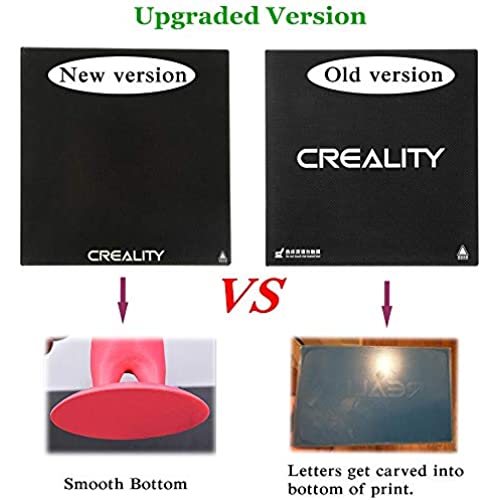

> 3 dayIm printing on the smooth side with PLA, and with a raft. I clean the plate with isopropyl alcohol before every print. I print the first layer at 80 degrees C, and the rest of the print at 65 degrees C; no hairspray, no glue sticks. Adhesion is fine during the print, and the part effortlessly removes once cool; dont have to pry it off. The only issue I have encountered so far is that the parts tend to warp at the corners; the raft corrects this. I havent experimented with temp settings beyond this, so there may be some other combination that works better.

-

Erik G.

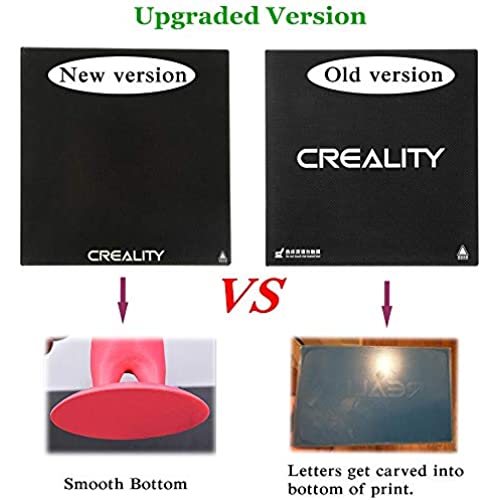

> 3 dayBeen using for a bit and havent had any issues yet. Printed dozens of items and all stick and release super easy. There are a couple of different textured glass beds similar to this, and they all work the same way. When the glass bed is heated and printing, the plastic sticks to the texture on the glass since it has little divots. Much easier than just plain glass that is too smooth and wont adhere correctly unless it is perfectly leveled and cleaned. Then once the glass cools, the textured material actually contracts, popping off the print. No need to pry anything off, just a little push or pull and it pops right off. Tip: dont use any glue or anything like that. Just keep it clean and it will work as intended. Also, many people like to use binder clips to hold bed surfaces down, but they get in the way and annoy me. Just use some masking tape along some of the edges and it will stick fine, as shown in my picture.

-

Patrick

> 3 dayI was blown away with the improvement to my printer with this board. It is SUPER quiet now and I have had no problems since the installation.

-

Walliddog

> 3 dayThe plate is over twice as thick, which causes the clips to come with the ender 3 to not work. You will also likely have to raise the z axis stopper. After calibration and leveling, it has poor adhesion fresh out of the box, at both default and adjusted heat levels. The plate may work well for other printers, but there are better options for the ender 3.

-

Madisyn Borer MD

> 3 dayDidnt receive the clips.