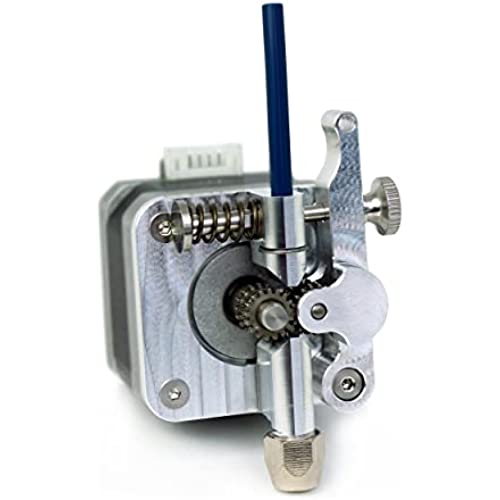

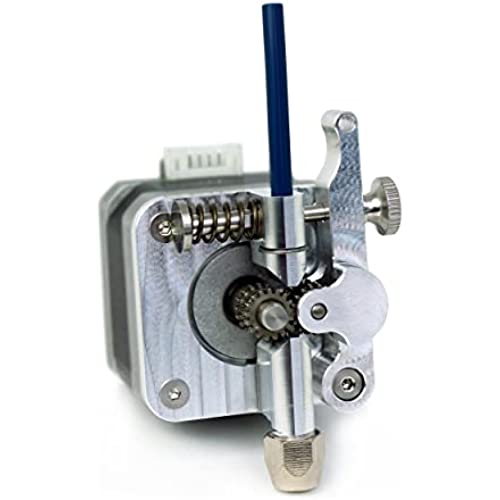

Micro Swiss Bowden Dual Gear Extruder Compatible with Creality Ender, CR10, CR-10 Pro, CR-10S, CR6-SE, Tornado

-

Adam

> 3 dayUpgraded my basic CR-10 printer extruder to this gear after I was having a lot of issues with slipping gears and not enough power to push the filament through to the hot end. This upgrade solved the issue! I did also have to purchase a new CR-10 motor for the extruder with the D shaped shaft to make this compatible, but that was a cheap purchase which ultimately made my printer function 10x better. Definitely a good product, high quality, and easy to install. Definitely recommend this thing!

-

Steven B.

> 3 dayLess than 3 days of use, not even running 24/7. Grinding noise coming from extruder. Upon further inspection, the drive gear broke off around the grub screw causing it to skip and ultimately allow the motor to spin freely.

-

Ken Nabbe

> 3 dayAs part of the installation, you need to cut the bowden tube from the extruder into a 45 degree point. That was annoying, trying to bevel it correctly. I would have preferred an included tube, with the cut already made. Other than that, it works well with PLA, Nylon and TPU.

-

Nathaniel Muzzy

> 3 dayAfter my metal Creality extruder bit the dust after 5 rolls of filament I looked for a dual-gear extruder, and I couldnt be happier with this one. it shipped fast, was easy to install, filament loads easily, and it shipped super fast. The machining quality looks good as well, and the design eliminates many of the weaknesses of the Creality model. Im confident that this extruder will last a good while.

-

Jim Jefferson

> 3 dayThis was by far one of the most painless upgrades for my Creality CR-6 SE. What prompted me to do it was the constant issues of the stock extruder clogging up and getting that dreaded popping noise and ruining print as a result. Microswiss includes directions and links to videos to guide you on the conversion. It uses your stock stepper motor and the only thing I recommend is keeping your line break sensor. Clip a piece of filament and put it in the sensor to keep it tripped on and keep it plugged in and tuck it under its original mounting spot. (you will rarely have line break issues). All i can say is I wish creality would use this dual allmetal gear for its BOWDEN setup stock.

-

Art Marchand

> 3 dayFor the price I thought I was getting a stainless steel part, but its all aluminum. It works so far.

-

Alan

> 3 dayEasy install and works like a treat. My only real complaint is it can bind up when pulling a lot of filament at once, like using the filament loader function on the community firmware.

-

Steven Parker

> 3 dayI cant believe it. I was shown how much difference an extruder can make. Yes Im a newbie, 8 mos. in. After a serious filament clog my stock plastic extruder started talking to me. Click, clack, what the heck was that, kind of noises. So I ran across this bad boy and made sure it would fit my Vyper. After a seamless installation I am beyond impressed by the results. Its like a new printer. It fits like a glove and machined to perfection. When it comes to moving filament NO HESITATION. I went from 425 esteps to 138. Extruder runs quiet as a mouse. NO DRAMA. Follow the instructions, however, in my case, when the wire harness was used it caused the motor to run backwards. Leave it alone on the Vyper, it works fine. But of course check it. I went with 3.5 mm retraction distance at 45mm speed. Left the flow alone, the test cube was perfect. Prints are awesome. I cant say enough about this thing.

-

Clint Vail

> 3 dayA beautiful piece. Vast improvement over the plastic stock extruder. Highly recommend. But follow the instructions.

-

JJ

> 3 dayEasy installation