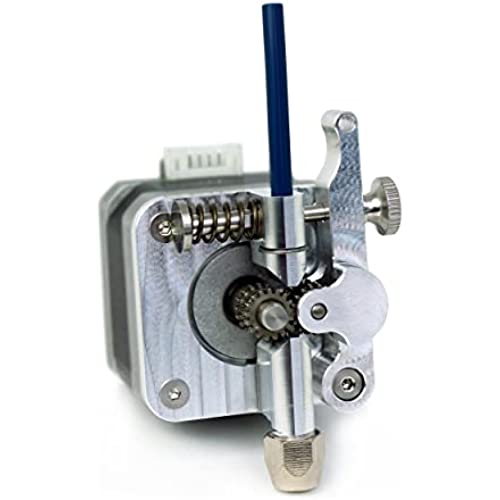

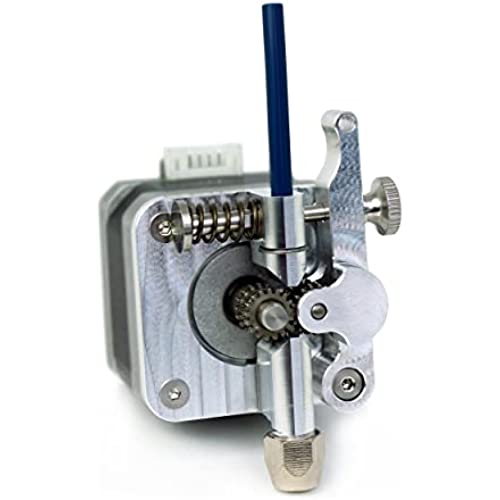

Micro Swiss Bowden Dual Gear Extruder Compatible with Creality Ender, CR10, CR-10 Pro, CR-10S, CR6-SE, Tornado

-

Douglas Hillman

> 3 dayGot my E5+ a few months back. Research had informed me that the stock plastic extruder was a weak point. Decided to get a replacement right off the bat. I wanted a dual gear Bowden and not red, so this fit the bill. :) I hadnt gotten around to installing it yet when my stock extruder broke after just three weeks. Realized then that I had a stepper motor with a pressed on gear. I could have muscled the gear off and milled a flat onto the shaft for the set screw in the new gear, but I just ordered another stepper instead. Theyre cheap and it doesnt hurt to have a backup. An E5+ will need a printed bracket to reposition the stock filament runout sensor if you want to keep it. If you dont have another printer and havent printed one before you need it, you can just stick a piece of scrap filament in the sensor and lay it aside while youre printing the bracket. The listed 130 steps resulted in a good bit of underextrusion. Based on measurements and the calculations on the Teaching Tech calibration web site, 137 is the proper number on my machine. Overall, a very well-made piece and a good upgrade, even over the metal extruders on some machines.

-

JD

> 3 dayEye-popping price. Despite the brand hype and good reviews, just couldn’t bring myself to do it for the longest time. That was a mistake. Could’ve saved myself plenty of wasted parts and product and under-extrusion headaches by opting for a genuine upgrade years ago. It’s been the best addition to my printing setup since I bought a can of Aqua Net hairspray and it’s making my old, original CR-10 shine again. Still think the price is outrageous, but the quality is undeniable. Super pleased with this product.

-

Shanold

> 3 dayThe Idea to use a brass crush ring to hold the boden tube in was a bad one. It works well but these tubes wear out and with no spares and No instructions on the Size of the crush connector to buy more Youre in for a world of Hurt if you ever have a issue with your Boden tube. The extruder works alright Doesnt seem worth the price It is High quality but I havent noticed a Huge difference between this and a cheap aluminum duel gear.

-

Adam

> 3 dayUpgraded my basic CR-10 printer extruder to this gear after I was having a lot of issues with slipping gears and not enough power to push the filament through to the hot end. This upgrade solved the issue! I did also have to purchase a new CR-10 motor for the extruder with the D shaped shaft to make this compatible, but that was a cheap purchase which ultimately made my printer function 10x better. Definitely a good product, high quality, and easy to install. Definitely recommend this thing!

-

Denny Sawyer

> 3 dayMicro Swiss put a good deal of effort into this design, overcoming pretty much all of the problems I had with the factory extruder on my Ender-3 Pro. First, the gears are much higher quality, and grip the filament better than the stock extruder, and the hardened steel gears will not wear out like the brass one did. Second, they moved the filament path to the outside, away from the Z axis rod (which is why you have to use the included reversing cable for the motor). Third, they constrained the filament path so that you can just insert the filament and turn the knob to load it - no more fidgeting with the filament to get it to go through the tiny little hole in the original extruder. And finally, its aluminum, so Im not worried about the lever breaking. The only concern I had with this kit was the fact that it uses compression fittings for the bowden tube, so if you ever have to replace the tube, youll need the correct size brass compression sleeve. They included a spare, but Id suggest buying a few extras. Also, do not overtighten the bowden fitting or you will compress the tubing and restrict the filament from going through it. Finger tight plus about a quarter turn should be sufficient - if you can still pull the tubing out, give it another quarter turn. Once I got it installed, I just keep the fitting finger tight and it holds the bowden tube securely, but I can still unscrew it easily if I need to cut the end off the filament. Finally, make sure you have the stepper motor with a D-shaped shaft. If you have one with a pressed on gear, youll want to replace it, because the plastic knob will not work with the press fit shaft, and youd need a gear puller to get the old gear off. The Creality motor costs about 15 bucks, which is less than a good gear puller, and makes installation much easier. As for the price, you really do get what you pay for. The cheap clone extruder I installed on my other printer has cost me more in wasted filament than I paid for the Micro Swiss, and I will soon be replacing it with the real deal.

-

J.M.

13-06-2025I have had inconsistent prints for 2 years. I always thought it my tramming was off, the filament was to wet, or my z offset was wrong. I have learned a lot about 3d printing and the fine adjustments one can make to compensate for these issues. I usually get decent prints after a few adjustments. My first layers have always been a bit sheet. Recently, I was having some serious dot dash stripping in my first layer after a filament snag failed a 1.5 day print. I spent a week troubleshooting the issue. I was so frustrated, because all the tricks I had learn to resolve first layer issues were not working. I had one print finally finish and it was a sponge. I crushed it with little effort. I finally took a close look at the stock brass (soft metal) filament feeder gears and noticed a rounding / bending of the teeth. First off, I didnt know the the filament feeder gear was brass, or I would have figured it out sooner. I picked up this bad boy for my birthday, and on my first print, I had the first layer put down so beautifully and so smooth I almost cried. The product is well made and easily put together. TIP: if you use a filament sensor and you print out the adjustment bracket provided by Micro Swiss, you will need to trim the tubing. I think the attached tubing is Capracorn PFTE. It is oil slick smooth. I think will order some as my next upgrade to replace the stock one I have. Micro Swiss has the quality you have been missing. This product will make your prints better.

-

Carhopper

Greater than one weekThis is great quality and a good improvement over my original one that came with the printer, but the runout sensor wont mount with this in place.

-

Richard C. Drew

> 3 dayMetal shavings stuck to the side of the top opening, damage to both sides of the bottom one. Id send it back but I need it today. Loust QC and obviously zero inspection. I was able to clean it up with a micro-file, but for a $50 extruder to have such an abysmal level of quality control? The manufacturer should be embarrassed.

-

Alan

> 3 dayEasy install and works like a treat. My only real complaint is it can bind up when pulling a lot of filament at once, like using the filament loader function on the community firmware.

-

Dustin

> 3 dayIts more expensive than the alternatives, but the quality is worth it by far. Id buy this again, and the customer service is great so no worries there! Also, it does not have the extrusion issues that the cheaper ones have, no extrusion inconsistencies.