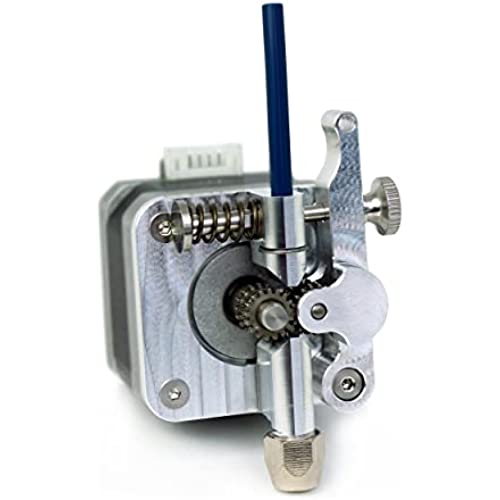

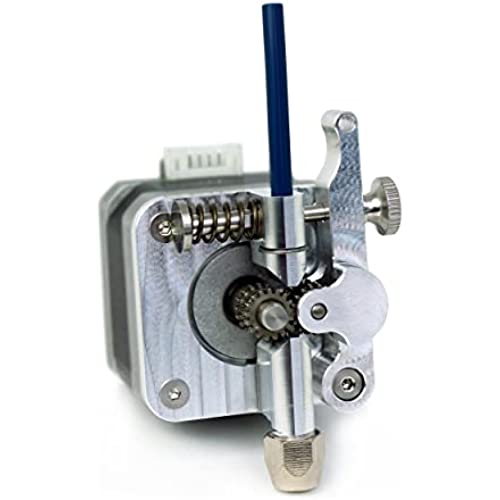

Micro Swiss Bowden Dual Gear Extruder Compatible with Creality Ender, CR10, CR-10 Pro, CR-10S, CR6-SE, Tornado

-

Nathaniel Muzzy

Greater than one weekAfter my metal Creality extruder bit the dust after 5 rolls of filament I looked for a dual-gear extruder, and I couldnt be happier with this one. it shipped fast, was easy to install, filament loads easily, and it shipped super fast. The machining quality looks good as well, and the design eliminates many of the weaknesses of the Creality model. Im confident that this extruder will last a good while.

-

Denny Sawyer

Greater than one weekMicro Swiss put a good deal of effort into this design, overcoming pretty much all of the problems I had with the factory extruder on my Ender-3 Pro. First, the gears are much higher quality, and grip the filament better than the stock extruder, and the hardened steel gears will not wear out like the brass one did. Second, they moved the filament path to the outside, away from the Z axis rod (which is why you have to use the included reversing cable for the motor). Third, they constrained the filament path so that you can just insert the filament and turn the knob to load it - no more fidgeting with the filament to get it to go through the tiny little hole in the original extruder. And finally, its aluminum, so Im not worried about the lever breaking. The only concern I had with this kit was the fact that it uses compression fittings for the bowden tube, so if you ever have to replace the tube, youll need the correct size brass compression sleeve. They included a spare, but Id suggest buying a few extras. Also, do not overtighten the bowden fitting or you will compress the tubing and restrict the filament from going through it. Finger tight plus about a quarter turn should be sufficient - if you can still pull the tubing out, give it another quarter turn. Once I got it installed, I just keep the fitting finger tight and it holds the bowden tube securely, but I can still unscrew it easily if I need to cut the end off the filament. Finally, make sure you have the stepper motor with a D-shaped shaft. If you have one with a pressed on gear, youll want to replace it, because the plastic knob will not work with the press fit shaft, and youd need a gear puller to get the old gear off. The Creality motor costs about 15 bucks, which is less than a good gear puller, and makes installation much easier. As for the price, you really do get what you pay for. The cheap clone extruder I installed on my other printer has cost me more in wasted filament than I paid for the Micro Swiss, and I will soon be replacing it with the real deal.

-

Shanold

> 3 dayThe Idea to use a brass crush ring to hold the boden tube in was a bad one. It works well but these tubes wear out and with no spares and No instructions on the Size of the crush connector to buy more Youre in for a world of Hurt if you ever have a issue with your Boden tube. The extruder works alright Doesnt seem worth the price It is High quality but I havent noticed a Huge difference between this and a cheap aluminum duel gear.

-

Kim Williams

> 3 dayThis is the best built, simple, easy to install, quality extruder I have ever used. This was installed on a Vyper and it really cleaned things up. Little pricey, but for quality Ill pay the additional.

-

Kyler

> 3 daySuper easy Install, built well and super quite operation good upgrade on my flsun sr

-

JJ

> 3 dayEasy installation

-

Theodora Friesen

Greater than one weekThe brass compression sleeve sucks. mine bent after a few prints and had to find out what the the exact size and get a replacement which was not easy. Other then that stupid part its great. works well on my cr6-se.

-

Katie

> 3 dayMy Anycubic Predators came with a 3:1 gear ratio extruder, which had gears and bearings and a lot of parts. The original extruder had a very high steps per mm (430), which gives it great resolution. One of the bearings disintegrated and I bought the micro swiss extruder to replace it. The micro swiss has a lot lower steps per mm (139), which is a lot less resolution, but it is built really well and has a lot less parts. For what i do, i favor reliability over precision. Time will tell, but im betting that the all-metal construction and simplicity will make it last longer than the OEM extruder. After printing with it, i dont see a noticeable difference on the benchy between the original extruder and the micro swiss. I have a feeling that the lower steps per mm on the micro swiss are still high enough to prevent visual defects. Seems like a great value to me!