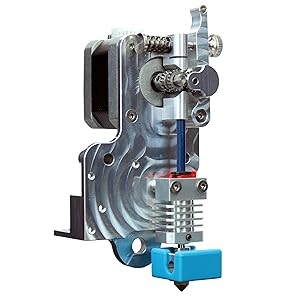

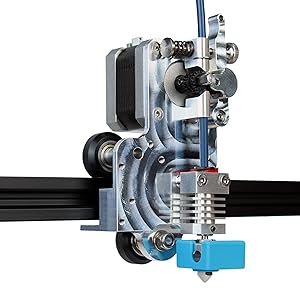

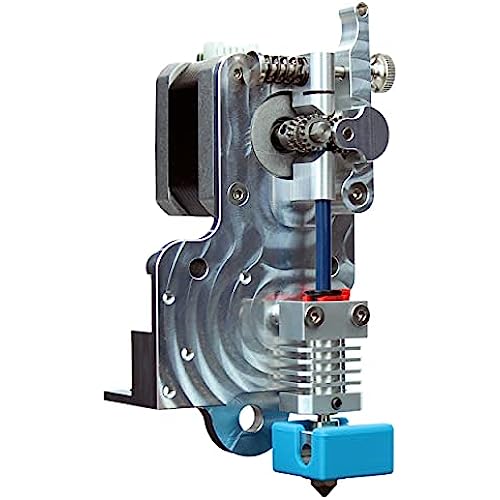

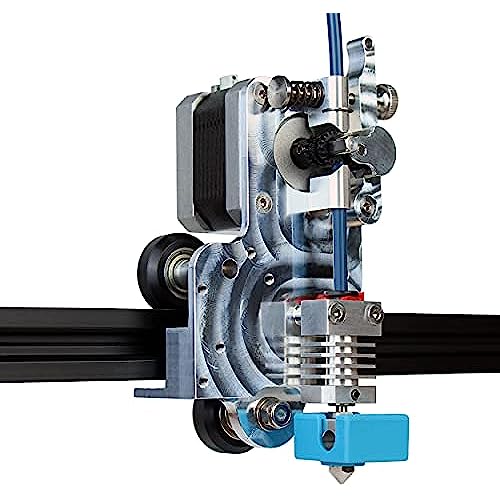

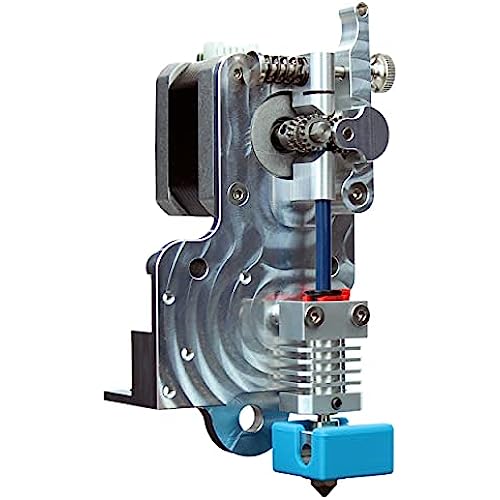

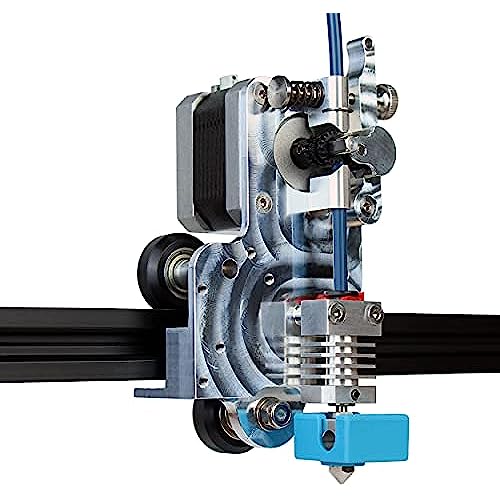

Micro Swiss Direct Drive Extruder for Creality CR-10 / Ender 3 Printers

-

lena

> 3 dayUsing ender 3 this direct drive/hotend combo made my prints great again when my stock head seemed like it had constant issues. The stock setup brass gear stripped out and hot end clogged non stop. This new Microswiss is a game changer for me.

-

Josh A.

> 3 dayI ordered this upgrade for my CR-10 after I had some sort of failure of the factory extrusion head that caused my heating block, heat sink, and fans to become a giant, fist sized ball of plastic. I had been wanting to go to direct drive for a while, based on experience with some other printers with it, and this failure was the push I needed to order the Micro-Swiss kit. The Micro-Swiss kit is exceptionally well made, the base bracket is machined aluminum, and it all fit together very easily following the video that is linked from their website. They include a small business card with a QR code that takes you to the video, which is nice. I did have one small issue, the countersink for the shoulder screw for the lever arm wasn’t quite deep enough, and as a result, the screw would pinch the lever arm tight against the base bracket when tightened down, rather than the lever arm floating on the screw shoulder. I fixed that with some very light filing of the back side of the lever arm pivot boss to effectively make it thinner, it took only a few passes of a fine tooth file to get it to fit as intended, so, I consider this within the regular fit and finish of installing something like this, but could be fixed at the factory by cutting the screw countersink jsut a hair deeper. I calibrated the steps on my CR-10 following a few videos off YouTube, and I settled on 139.25 steps per mm as optimal. One other thing that must be done is offsetting the X and Y home, as the true, limit switch driven home now hangs off the build plate a bit. I am getting beautiful extrusion with this direct drive kit; the dual mesh drive rollers really bite hard into the filament, and the heat brake works amazing. You can heat the head up, unload the filament drive lever, and pull the filament back out of the hot end no problem, and the end that comes out looks like it’s been clipped by a pair of scissors! No swelling of the end in the brake like some hot ends, no stringy tail, just a clean square end. The first time I pulled the filament back when doing the step calibration I thought it broke off in the extruder, but, 3 more tails exactly the same has me convinced The heat brake just works that good! I’m running a .8mm nozzle in my CR-10 at 70mm/s speed and this extruder kit has absolutely no issue keeping up!

-

Apple

> 3 dayI own an Ender 3 v2, I thinks its reasonable to say its a VERY popular start point. Having to print your own shroud is one thing, but theres no holes or bracket for mounting my CR touch. Its getting returned

-

Cameano

> 3 dayIve done a printed direct drive in the past for my Ender 3, and was printing and collecting parts to do the same on my CR-10, but as the designers of various systems do, they upgrade their prints and take down their previous designs, which can leave you out in the cold if you didnt download the original STLs. So I was having issues putting the new one together the same as the old one. I decided to buy this Micro Swiss direct drive extruder to see if it was worth the hype. I installed it this morning using the supplied instructions on their website (pdf download), and everything was straight forward. No hiccups. No leftover parts, and better yet, no trips to my bins to find missing hardware. This is great! Done in about an hour. Follow up with setting your offsets if needed, and youre done. Print quality is great too. I had been printing with a .6mm nozzle for a long time, as its a bit faster, and doesnt clog at all, but I forgot what quality of print you can get from a .4mm nozzle as is supplied with this setup. Looks great! Ive tried both ABS and TPU already, and both came out excellent!

-

2rainy2kayak

> 3 dayDon’t use flexible PLA with this, not matter how many adjustments I made the extruder would allow the Filament to escape and make a larger mess.

-

@mistgraf insta

> 3 dayGreat results o complaints

-

Cal

Greater than one weekDefinitely an upgrade from the stock extruder and hot end. The gears seem to have had (have) some messing issues so it took a bit to get the tension set just right, but overall very happy

-

Luis Roman

> 3 dayYou will need to fix your steps per mm and your retraction speed in your slicer program. I love the quality of the prints. Worth the money

-

Josh Thompson

> 3 dayAs I titled.

-

Daphney Bernhard

Greater than one weekI had clogging issues. It is a fault of Microswiss. If you have clogging issues. Look up thermal paste Microswiss either on reddit or google. Without that fix, I had clogging and nozzle leaking issues that didnt matter the settings I tuned to. It is a cheap fix and something microswiss needs to include in the kits. Directdrive setup is perfect. Printing PLA, PLA+, PETG, TPU nicely now.