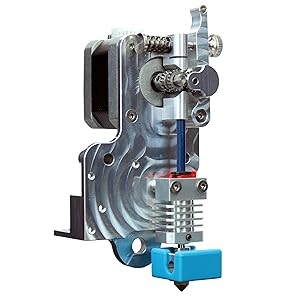

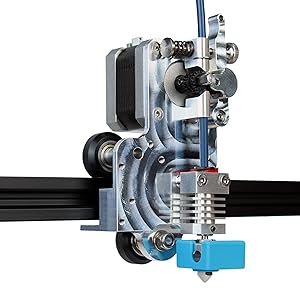

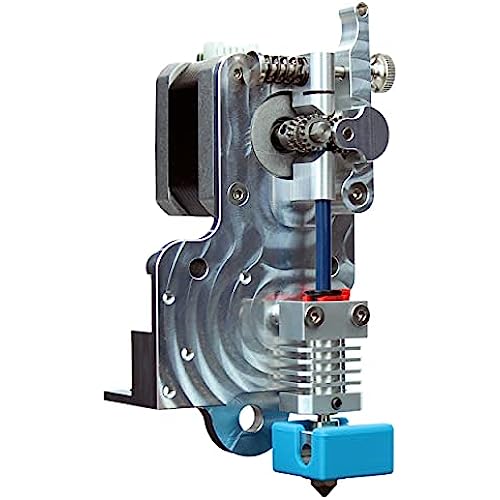

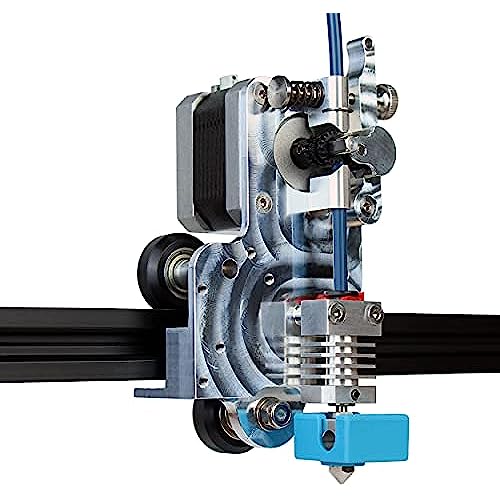

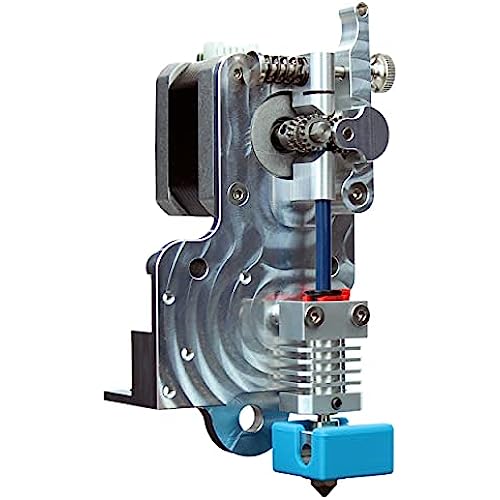

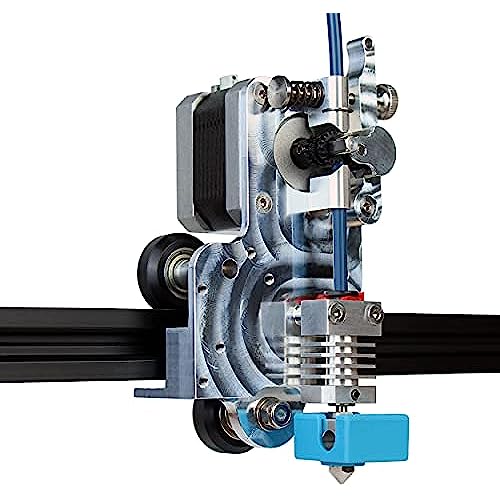

Micro Swiss Direct Drive Extruder for Creality CR-10 / Ender 3 Printers

-

Saul Dominguez

Greater than one weekGot this just in time, shipped right away. Opened the box and you can see everything is in there nothing is missing. Everything looks like it’s good quality material and well made. Can’t wait to start big projects.

-

Kim Collins

> 3 dayWhile this extruder looks high quality with beautifully machined and polished aluminum, I must say Im not impressed with the design. It consistently has TERRIBLE jamming problems when printing TPU, which is one of the filaments direct-drives are supposed to be better at. It also tends to conduct a lot of heat to the motor, as its mounted directly to the aluminum plate which gets quite hot. There really should be a thermal barrier. Overall I am not impressed given the very exuberant price. The OMG extruder is less than half the price, is more configurable, and performs much better.

-

The Driveway Engineer

> 3 dayListed as a bolt on, not a bolt on. Now Im going to have to pay someone to print me a EZABL mount for it.

-

Goji

> 3 dayFixed a good bit of my issues with the stock extruder! Be aware that with the extra weight you may have to look into getting dual Z, just a little deeper into the rabbit hole. All in all, solid upgrade!

-

Wellington Kris

> 3 dayIf you want to be totally unable to print PLA, get this. It clogs all the time. Heat creep is a major issue and the hot end is completely worthless. So either get a bimetal heat break or stay with what you have. The direct drive bracket is kind of nice. Light and solid. Im unsure about the extruder since the clogs stop me from using it. Worst upgrade Ive ever bought.

-

William Heimbigner

> 3 dayThis was my first real upgrade to my Ender 3 Pro, after having screwed up and clogged numerous nozzles trying to print PETG at a temperature hotter than the stock 3 Pro can really handle. One HUGE warning: Look at the extruder motor included with the Ender. If, in the center of the gear, you you have a perfectly circular steel pole, you MUST get a new motor. If, in the center of the gear, you have a pole that makes a D shape, youre good, no new motor needed. Id strongly caution against the DIY attempts to chisel the circle-motors into a D shape... these motors need to be able to step to a degree of ~130 clicks just to move filament a single millimeter... that takes an extreme amount of precision that you dont want to mess with. Just spend the extra $20 to get a new motor. The installation process for this Id describe as tiring, but easy. The YouTube videos were easy enough to follow. After installation, the printer tweaking was EXTREMELY easy. I had to change my extruder e-steps, and my Y offset, and re-level the bed... that was it. This should be considered an absolute top priority upgrade to the Ender 3 Pro for printing.... literally anything other than PLA. VERY happy with this product.

-

Matt Pitta

> 3 dayThis is single-handedly the best upgrade for the cr10s pro v1. Hands down…. Make sure your esteps are set properly, and pair this with solid bed mounts and a bl touch. Game changer for cr10’s!!!

-

Cameano

Greater than one weekIve done a printed direct drive in the past for my Ender 3, and was printing and collecting parts to do the same on my CR-10, but as the designers of various systems do, they upgrade their prints and take down their previous designs, which can leave you out in the cold if you didnt download the original STLs. So I was having issues putting the new one together the same as the old one. I decided to buy this Micro Swiss direct drive extruder to see if it was worth the hype. I installed it this morning using the supplied instructions on their website (pdf download), and everything was straight forward. No hiccups. No leftover parts, and better yet, no trips to my bins to find missing hardware. This is great! Done in about an hour. Follow up with setting your offsets if needed, and youre done. Print quality is great too. I had been printing with a .6mm nozzle for a long time, as its a bit faster, and doesnt clog at all, but I forgot what quality of print you can get from a .4mm nozzle as is supplied with this setup. Looks great! Ive tried both ABS and TPU already, and both came out excellent!

-

St0mp

> 3 dayI have a ender 3, 2 CR-10S Pros, Prusa MK2.5, and a CR-10S. I installed this hotend on my CR-10S its been collecting dust, I use my pros most of the time. Installing this hotend on my CR-10S has now turned my CR-10S into my printer of choice to run. Now my CR-10S pros are collecting dust going to have to get them upgraded soon.

-

Mark E Mark

> 3 dayHot end leaked and melted and caused fire alarm to go off. Most people print over night. Scary stuff. Changed to 4 stars as Micro Swiss came through with a replacement. Thank you Micron Swiss