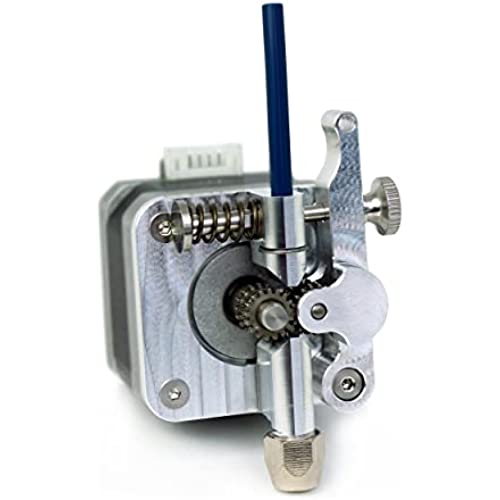

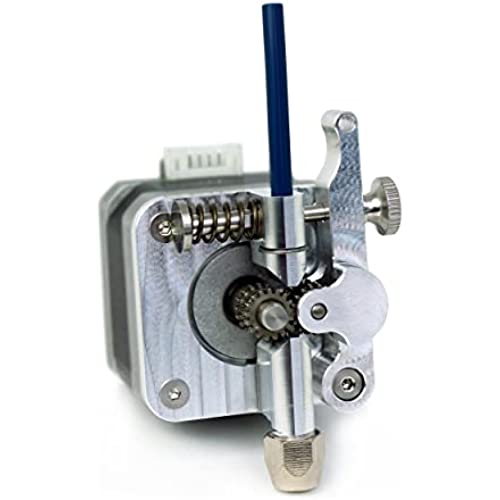

Micro Swiss Bowden Dual Gear Extruder Compatible with Creality Ender, CR10, CR-10 Pro, CR-10S, CR6-SE, Tornado

-

JKC

> 24 hourI noticed inconsistencies in print for my Creality CR-6 SE printer. I also heard clicking noises coming from the Extruder. I did several 100 mm E Steps calibration runs and observed 99 mm 1st run, 92 the second, and 93 on the third. I tightened the spring as far as it would go on the Extruder with no improvement in results. After reading online compliant after complaint regarding the cheap plastic Extruder that comes with the CR6, I decided an upgrade was in order. There appears to be no drop in replacement Extruder for the CR-6. Modifications are required for any upgrade to align the Extruder filament input to the Filament Run Out Sensor. I found several designs for an adapter that installs below the Run Out Sensor for this Micro-Swiss Extruder but didnt find any for the many other cheaper Extruders from China that are available on Amazon. I could have most likely came up with a method to adapt one of these however I liked the way the Micro Swiss was constructed and that it was dual geared and decided to pay the higher price. I installed it in my CR-6 and couldnt be more happy. Each 100 mm calibration run measured 100mm. My print quality is the best its ever been. The product is made in the USA where its difficult to compete with Chinas labor rates so instead of trying to compete on price they competed on quality. To install go to the Micro Swiss website. They have detailed installation instructions with a link to an STL file for the Run Out Sensor alignment adapter. The kit comes with a reversing adapter harness that must be inserted on the stepper motor harness. The filament on the stock Extruder routes in front of the stepper motor gear and requires a counter-clockwise motion to advance the filament. The Micro Swiss Extruder routes the filament behind the gear and requires a clockwise motion to advance the filament. The provided adapter harness reverses the stepper motor direction. The gear size is different so you will need to modify the E Steps within the printer. Without this adjustment your printer will under extrude filament. This can be achieved with the G Code file provided on the Micro Swiss webpage. Simply run this G Code as if you were printing a design. It can also be programmed and if desired fine tuned or calibrated using and App like Prontoface. Detailed instructions for performing this method can be found at the all3dp website. If you have problems getting Prontoface or any other terminal to talk to your CR-6 (probably true for all Enders also) make sure you set your computers interface and Prontoface baud rates to 115200. Many including myself have struggled a while with this. One of the gears has already been mounted into the lever. When installing the other gear to the stepper motor shaft, make sure to carefully align the 2 gears to match. At first I didnt get mine perfectly aligned and had difficulties getting the filament to thread and damaged my Capricorn Bowden Tubing. My old eyes had difficulty seeing both gears. To properly align, I inserted a #22 drill bit backwards (5/32 works too) into the output side of the extruder up to the gear and center the gear to the drill bit.

-

Matt Nims

> 24 hourWorks great on a anycubic vyper

-

Edwin Combs

> 24 hourI really like this bowden extruder. Its well built and a huge improvement over what came with the printer.

-

Jeff Garland

> 24 hourThis thing is made like a swiss watch. I have zero complaints about the item, or packaging or installation. I never got consistent output with this no matter the temp or tension or speed. I tried and tried and really wanted to use this. I have been printing almost non stop for maybe 5 years. I have tried pretty much any filament and extruder you can imagine but I could not get this to work. After days of trial and lots of errors I ended up pulling it and installing one of the $14 MK8 red dual gear extruders. Immediately, the mk8 did a 14 hour print flawlessly. The microwiss just didnt seem to grab the pla, petg or nylon filament as well. I dont want to totally dog it. It has a good reputation and is made VERY well. Just didnt work for me.

-

Dustin

> 24 hourIts more expensive than the alternatives, but the quality is worth it by far. Id buy this again, and the customer service is great so no worries there! Also, it does not have the extrusion issues that the cheaper ones have, no extrusion inconsistencies.

-

Ken Nabbe

> 24 hourAs part of the installation, you need to cut the bowden tube from the extruder into a 45 degree point. That was annoying, trying to bevel it correctly. I would have preferred an included tube, with the cut already made. Other than that, it works well with PLA, Nylon and TPU.

-

David Serna

> 24 hourSo far, its been running great, I ran 2-day prints with it and no grinding with metals since its high-quality metal its been running. Id strongly recommend it, it takes a bit more money, but its very much worth the price for the longevity of your printer!

-

alex butte

> 24 hourDoes a great job and easy to install the instructions are really straightforward did have to calibrat my steps after install but worth every penny.

-

Houston rn

> 24 hourEasy to install and lots of info on thier website to help tune an calibrate. Just make sre to use the short cable included because the position will mKe it feed backwards. The short cable reversed it and now it works flawlesly.

-

Nemo

> 24 hourThis print was taken straight from the printer... no spider webs... This combined with the Hero printhead mod drastically improved my printing... I also think my popup enclosure helps as I keep my house on the cold side.