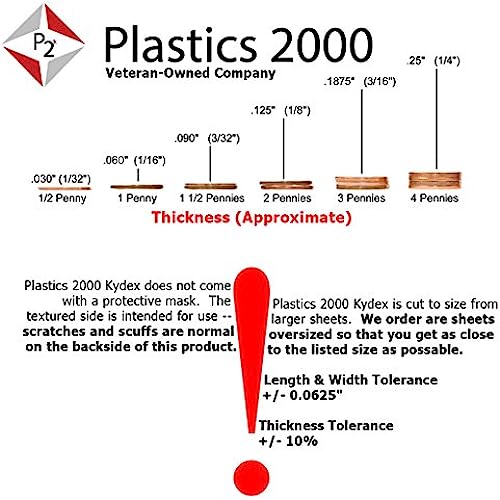

Plastics 2000 - KYDEX Sheet - 0.080 Thick, Black, 8 x 12, 2 Pack

-

Ronald Y.

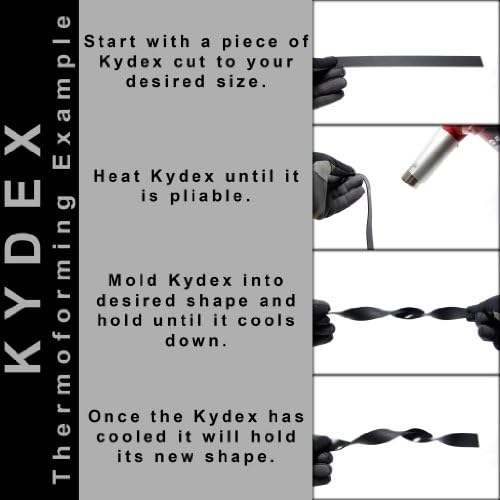

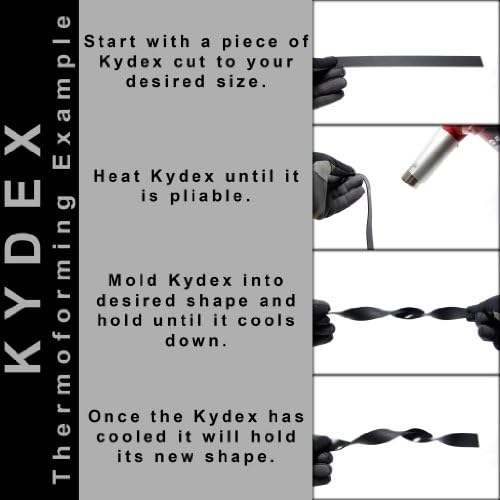

> 24 hourI used this for my 2003 Zuma 50. In the process of modifying the frame and I had to cut out a portion of the storage compartment. A buddy told me about this stuff so I gave it a shot. From what I understand, using a heatgun to mold this can be pretty time consuming. Luckily, I have a powdercoating oven. Just cranked it to 350F and waited for the material to reach 290F to 300F (about 15 min). Laid it down in the scooter tub and it only took about a minute to cool down. I used some 5-minute epoxy to glue it to the tub and that was that! Easy peasy. Love this stuff.

-

A. Phibbs

> 24 hourExactly what I was expecting, and stamped made in USA right on it.

-

Sean P

> 24 hourLoved it! Worked out perfectly

-

Antoinette Boyer DVM

> 24 hourItem arrived as described

-

Jstanker

> 24 hourJust what I was looking for to make an adjustable cheek rest

-

Gabriel D.

> 24 hourShapes well and is solid.

-

Lacey

> 24 hourDurable material. Worked well as a homemade car stereo dash kit. I even had enough left over for a nice holster.

-

Prometheus Agamemnon

> 24 hour(Dont judge the hosler quality on the kydex. Made both as test runs in about 10 minutes each total) Love it. Durable, easy to work. ZERO cracks or scratches in the kydex. Takes a minute or less to heat in an oven, so if youre new and looking for some, keep that in mind.

-

Mr. Dave Ruecker

> 24 hourHusband loves it. Great product.

-

Zack

> 24 hourDid not heat well or form well at all. Would never buy this again.