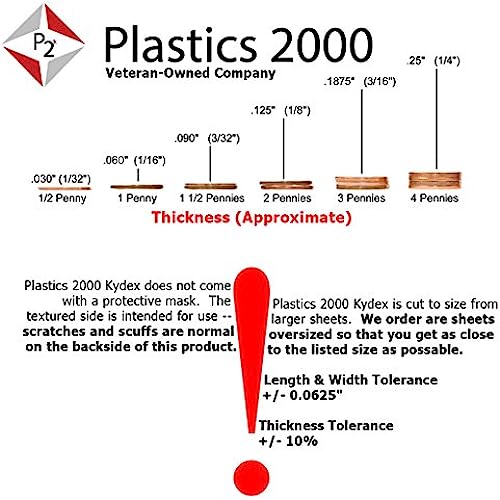

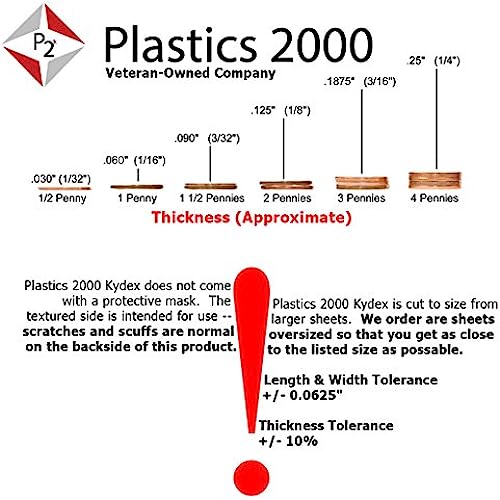

Plastics 2000 - KYDEX Sheet - 0.080 Thick, Black, 8 x 12, 2 Pack

-

✋️

> 3 dayPricey plastic but I made two holsters w them, second was better than the first attempt

-

Zack

> 3 dayDid not heat well or form well at all. Would never buy this again.

-

brenda

> 3 dayThick and sturdy pieces

-

T.R.

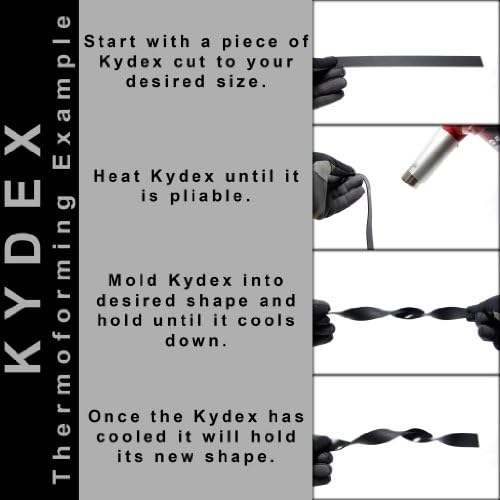

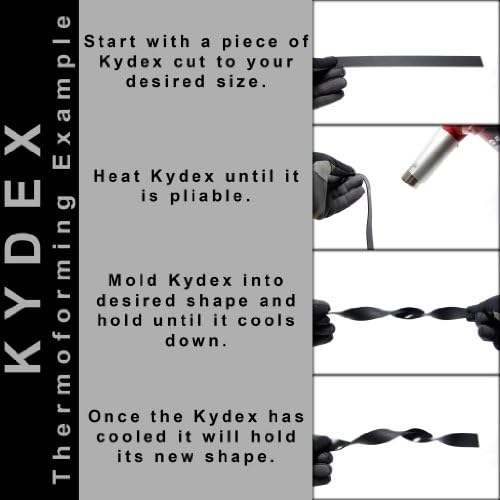

> 3 dayMy first experience working with kydex. Heated it up on my old griddle and molded it into shape. Got a crease in the kydex I didnt like so I reheated it and tried again. Worked great.

-

J. Green

Greater than one weekThis is good quality kydex. I have used it for several knife sheaths and a few holsters so far. Great price on it as well.

-

bryan

> 3 dayI heated it up in the oven and shaped it as needed. Very easy to work with

-

Prometheus Agamemnon

> 3 day(Dont judge the hosler quality on the kydex. Made both as test runs in about 10 minutes each total) Love it. Durable, easy to work. ZERO cracks or scratches in the kydex. Takes a minute or less to heat in an oven, so if youre new and looking for some, keep that in mind.

-

CK Custom Knives

> 3 dayPerfect for my knife sheaths

-

Unbelievable

> 3 dayOne of the best kydex sheetings. Used this exact kydex befor and works wonders

-

Bill West

Greater than one weekwith a simple heat gun the material quickly become pliable and easy to shape. I plan many more projects with Kydex.