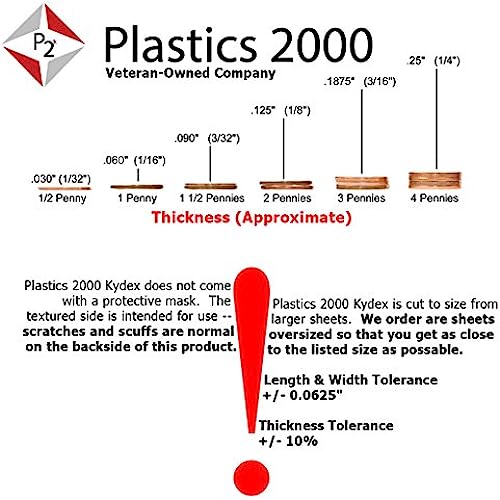

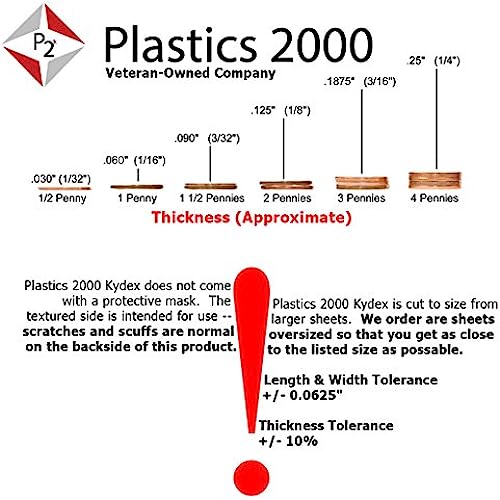

Plastics 2000 - KYDEX Sheet - 0.080 Thick, Black, 8 x 12, 2 Pack

-

Ramano sabastian

> 24 hourQuality material

-

edward Kerns

> 24 hourI have an acoustic guitar, bought used, that had a small hole cut in the side to install a pickup. I needed to patch the hole in an area with a compound curve. Without a lot of expense a proper repair just wasnt practical, so I molded a piece of Kydex to the right shape, and used double faced tape to cover the hole. Not perfection, but not bad!

-

Antoinette Boyer DVM

> 24 hourItem arrived as described

-

Brian E.

> 24 hourMade rc car diffusers, splitters, brackets. Very durable and strong.

-

Jamie

> 24 hourGreat product worked great for the use I bought it for.

-

Edward Scott Allen

> 24 hourAbout this product to make combination plates for vintage Kustom Amplifiers I found that it was best to cut this Kydex on my tablesaw because it gave a clean edge. I would not recommend using a bandsaw or a jigsaw For cutting into pieces, or knife blades, the jig saw and the band saw blades possibly were not the proper choice for the job.

-

Belle Crist

> 24 hourGreat

-

CILIO J PACHECO

> 24 hourUsed this to make cheek risers for my rifles. Worked perfectly.

-

Cameron

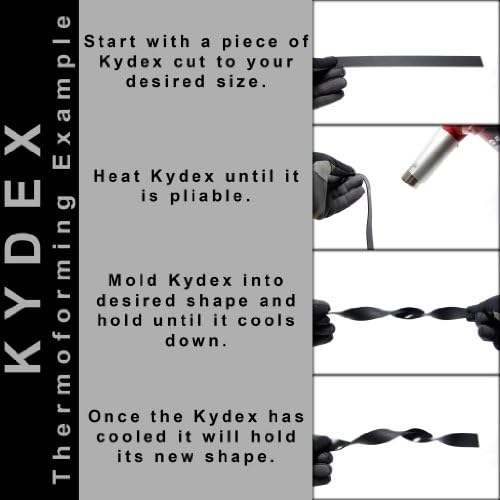

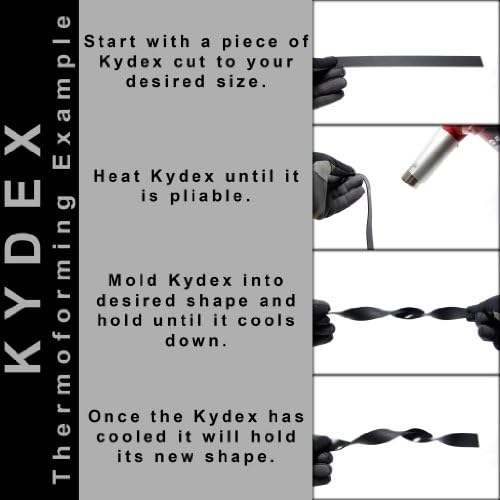

> 24 hourThis stuffs pretty neat. It was my first time using kydex. It was very forgiving. I tried it at 200 and 300 degrees Fahrenheit. Messed up several times and re-heated the sheets of kydex. Seemed to come out fine!

-

Fishook

> 24 hourGreat for models