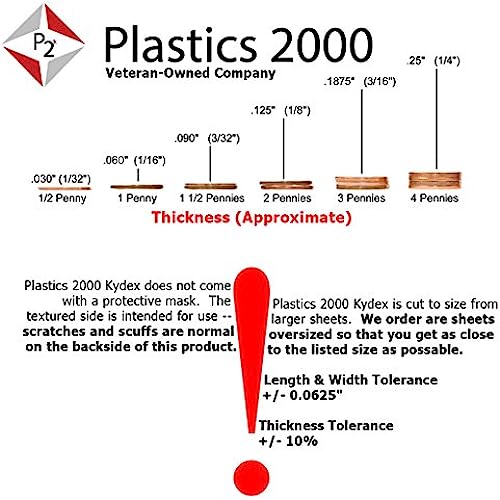

Plastics 2000 - KYDEX Sheet - 0.080 Thick, Black, 8 x 12, 2 Pack

-

Cameron

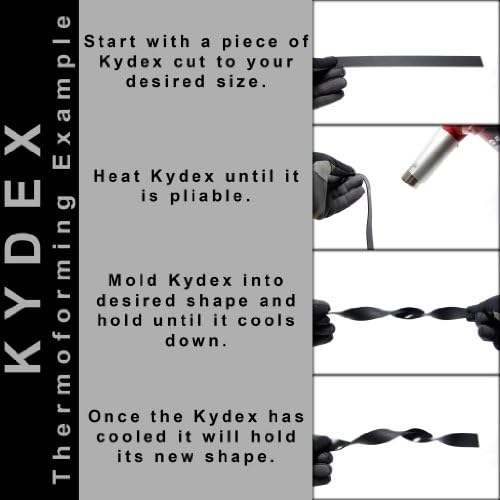

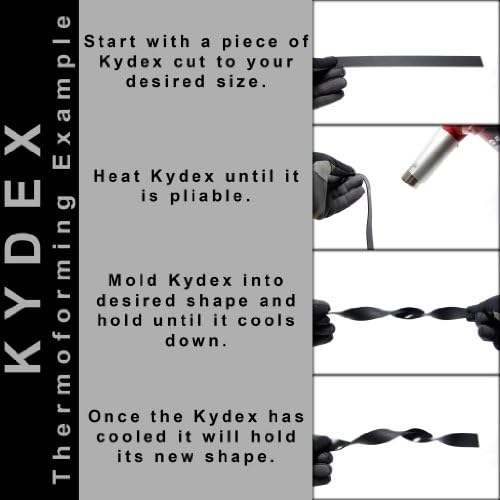

Greater than one weekThis stuffs pretty neat. It was my first time using kydex. It was very forgiving. I tried it at 200 and 300 degrees Fahrenheit. Messed up several times and re-heated the sheets of kydex. Seemed to come out fine!

-

David

> 3 dayDecent priced a little high for only two pieces but it does good.

-

CILIO J PACHECO

> 3 dayUsed this to make cheek risers for my rifles. Worked perfectly.

-

brenda

> 3 dayThick and sturdy pieces

-

ladymad

> 3 dayknife case

-

Kindle Customer

> 3 dayGreat price great product.

-

Frank J. Rodriguez

> 3 dayCan’t tell u how I liked the product cuz I can’t use it, cuz it did not come with instructions!!

-

theconstantrunner

> 3 dayGood product. Easy to mold with a hair dryer; probably easier with a heat gun. For those complaining how hard it is to cut - use tin snips. Or those sheers for sheet metal. Whatever you call it. Cuts it like butter and straight lines without having to warm it up. Dont use house scissors... it wont cut.

-

Jeremy

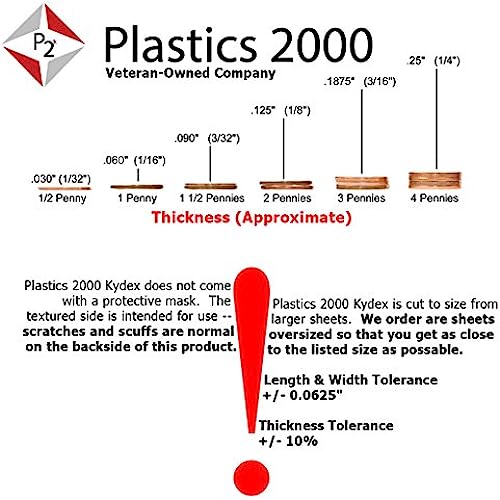

> 3 dayKydex is great and quality is good. One note for buyers: the sheets I received are now 8x12, they are 7 7/8 x 11 7/8. If you need a 12” sheet, this will not work.

-

Gcarroll73

Greater than one weekPerfect for my sheath making.