Plastics 2000 - KYDEX Sheet - 0.080 Thick, Black, 8 x 12, 2 Pack

-

Gcarroll73

Greater than one weekPerfect for my sheath making.

-

Kev

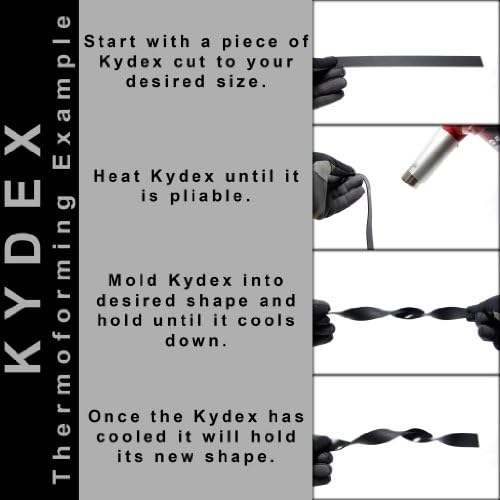

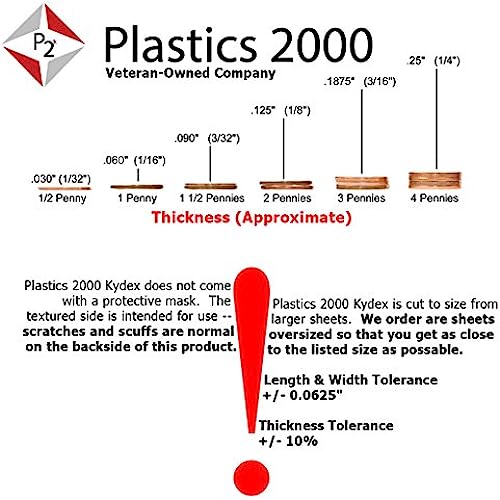

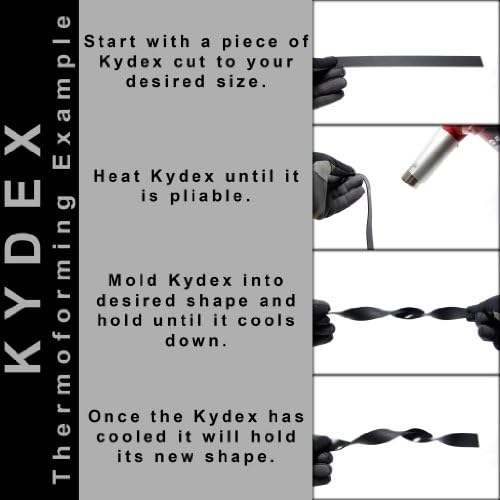

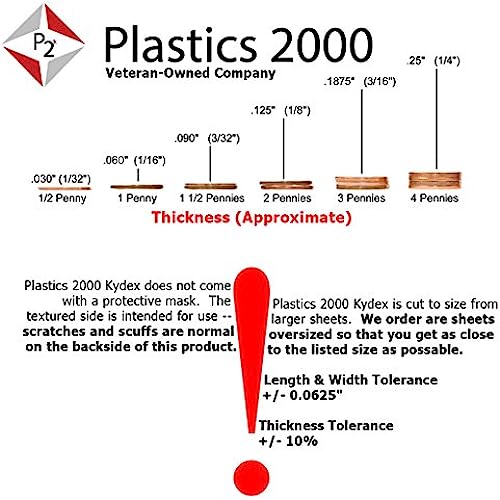

> 3 dayFor my first time working with Kydex I would say this is a win. Using a heat gun on low I was easily able to form a small section after scoring it with a utility knife and snapping off what I needed. I did a holster strut repair which looks as good as the original and seems more sturdy using the .080, the original was .060.

-

Sgt Apone

> 3 dayRough and satin on one side, not as rough and a little glossier on the back. Score it a few times and break it off. Very sturdy for the thickness. Worked perfect for the project I bought it for.

-

Ki

> 3 dayPerfect, just what I was looking for.

-

Dan Bradley

> 3 dayFound heating in the oven much better than a hair dryer, lol. molds very well and was easy to trim. nice product.

-

T.R.

> 3 dayMy first experience working with kydex. Heated it up on my old griddle and molded it into shape. Got a crease in the kydex I didnt like so I reheated it and tried again. Worked great.

-

Mary & Vinnie

> 3 dayNot the best price but it came fast and it came as described.

-

samuel

> 3 dayThat said it works well.

-

Robert F

> 3 dayCame as expected. Uniformly thick sheet. A small line of discoloration where it looks something was dragged across it but otherwise fine. Reacts to heat gun well.

-

Parker Geurin

> 3 dayMade a knife sheath and an axe cover Andy still have an entire sheet left. Works great!