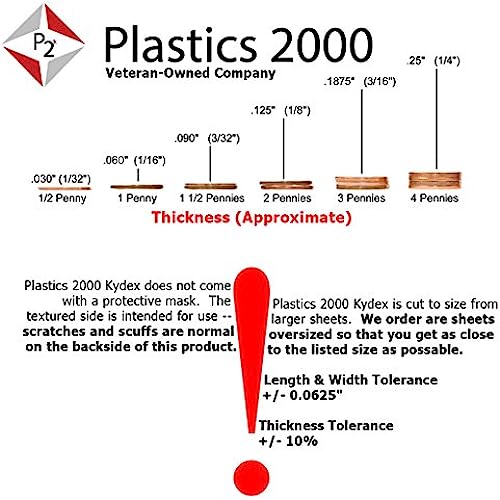

Plastics 2000 - KYDEX Sheet - 0.080 Thick, Black, 8 x 12, 2 Pack

-

A. Phibbs

> 3 dayExactly what I was expecting, and stamped made in USA right on it.

-

Lacey

> 3 dayDurable material. Worked well as a homemade car stereo dash kit. I even had enough left over for a nice holster.

-

brenda

> 3 dayThick and sturdy pieces

-

Robert F

> 3 dayCame as expected. Uniformly thick sheet. A small line of discoloration where it looks something was dragged across it but otherwise fine. Reacts to heat gun well.

-

travelin fool

> 3 dayProduct arrived on time and exactly as described. I used it to make a mold for a concealed carry handgun and the product performed as expected.

-

Bill West

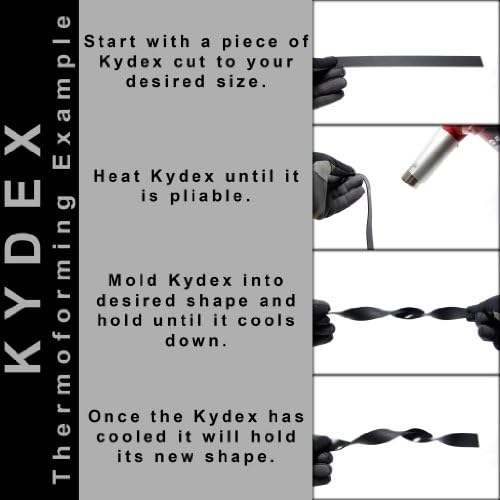

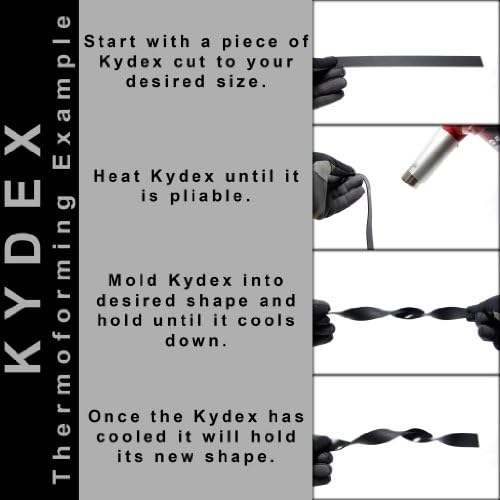

> 3 daywith a simple heat gun the material quickly become pliable and easy to shape. I plan many more projects with Kydex.

-

Prometheus Agamemnon

> 3 day(Dont judge the hosler quality on the kydex. Made both as test runs in about 10 minutes each total) Love it. Durable, easy to work. ZERO cracks or scratches in the kydex. Takes a minute or less to heat in an oven, so if youre new and looking for some, keep that in mind.

-

Ramano sabastian

> 3 dayQuality material

-

Chad Bahringer

> 3 dayPerfect size for my holsters n sheaths

-

Frank J. Rodriguez

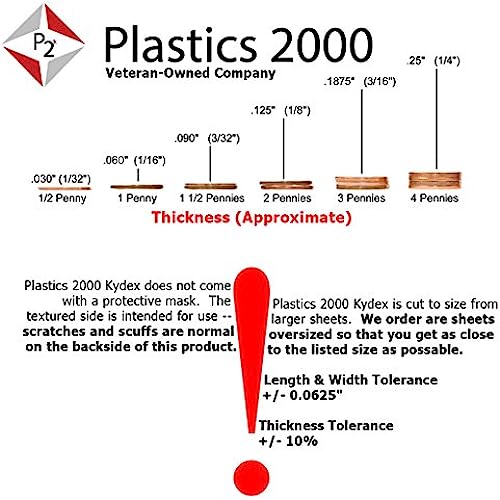

Greater than one weekCan’t tell u how I liked the product cuz I can’t use it, cuz it did not come with instructions!!