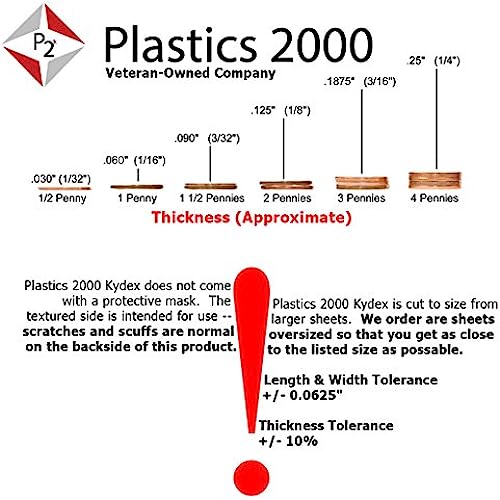

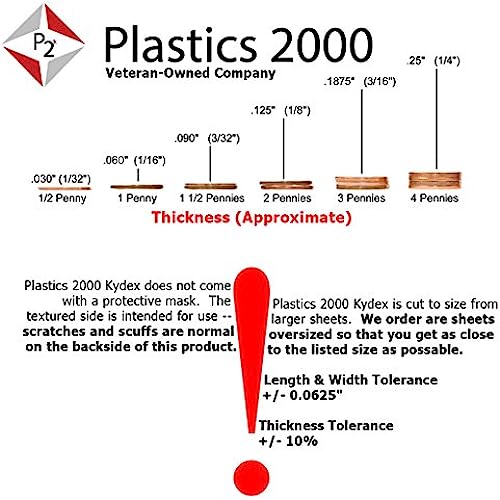

Plastics 2000 - KYDEX Sheet - 0.080 Thick, Black, 8 x 12, 2 Pack

-

Gcarroll73

> 3 dayPerfect for my sheath making.

-

bryan

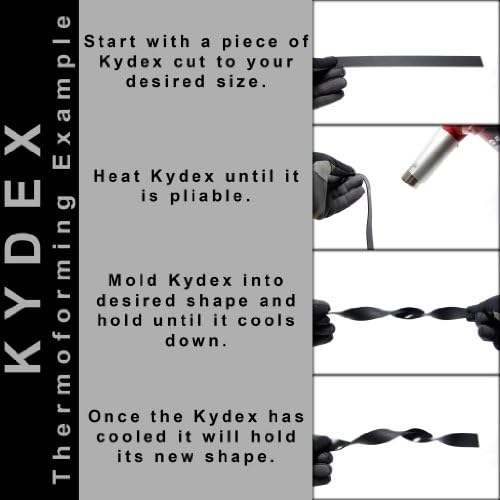

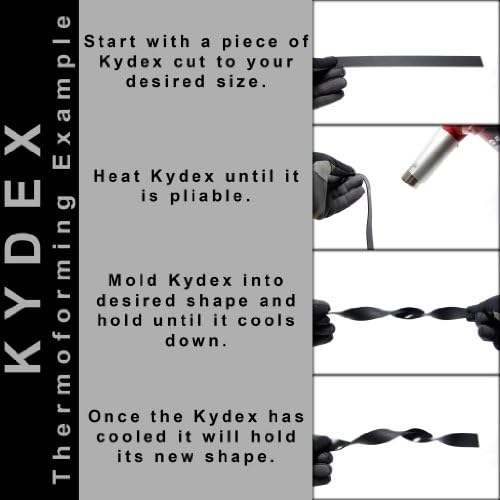

> 3 dayI heated it up in the oven and shaped it as needed. Very easy to work with

-

J. Green

> 3 dayThis is good quality kydex. I have used it for several knife sheaths and a few holsters so far. Great price on it as well.

-

Mark

Greater than one weekI made a minimalist holster for my carry firearm. The product is easy to shape and very strong.

-

Mr. Dave Ruecker

> 3 dayHusband loves it. Great product.

-

Jay

> 3 dayNo complaints but it think the price is a bit steep, $5 for a piece of plastic seems a little ridiculous

-

Keene

> 3 dayIf you ever felt ripped off over a kydex sheath buy some and give it a go. Easy to work with and a good thickness.

-

Len Hill

> 3 dayGood stuff

-

Justin

> 3 dayOnce you get tha hamg of working with it, it is super easy to make holsters or sheaths for whatever you need

-

Josh

Greater than one weekGood sturdy plastic. Was expecting it to be a little more flexible, luckily it is a thermoplastic, so I can heat and mold to shape. Would, and probably will buy again.